GN Solids Control, a global leader in drilling waste management solutions, has completed the delivery of two custom containerized dewatering systems to an overseas client, marking a significant milestone in the company’s international expansion.

Each system integrates five core components engineered by GN SOLIDS CONTROL:

GNCD930G-GP Cutting dryer:The flagship model features a dual-cone drum and variable frequency drive, achieving a throughput of 90m³/h with 95% solids recovery. Its body is branded with the GN SOLIDS CONTROL logo, ensuring traceability and quality assurance.

1.5x2x1.2m Storage Tank:Coated with corrosion-resistant material, the tank is spray-painted with GN SOLIDS CONTROL’s emblem and safety instructions, optimizing durability for hazardous fluids.

Custom Screw Pumps:Designed for consistent pressure delivery, these pumps synchronize with the centrifuge via GN SOLIDS CONTROL’s intelligent control system. Technical specifications are engraved on the pump plates.

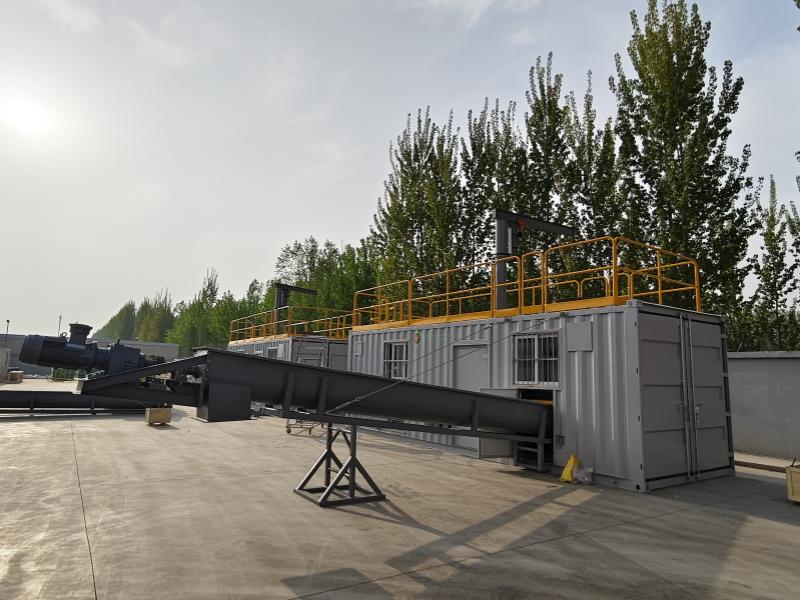

Modified Shipping Containers:Retrofitted by GN SOLIDS CONTROL’s engineering team, each container integrates power distribution and lifting points. The side panels prominently display “GN SOLIDS CONTROL SYSTEMS,” enabling rapid on-site deployment.

Anti-Clogging Screw Conveyors:Equipped with wear-resistant liners and a patented feeding mechanism, these conveyors bear the GN SOLIDS CONTROL insignia, ensuring seamless solids transfer.

GN SOLIDS CONTROL plans to expand its overseas footprint with similar turnkey solutions, leveraging the success of this delivery to solidify its reputation as a trusted partner for resource-intensive industries.