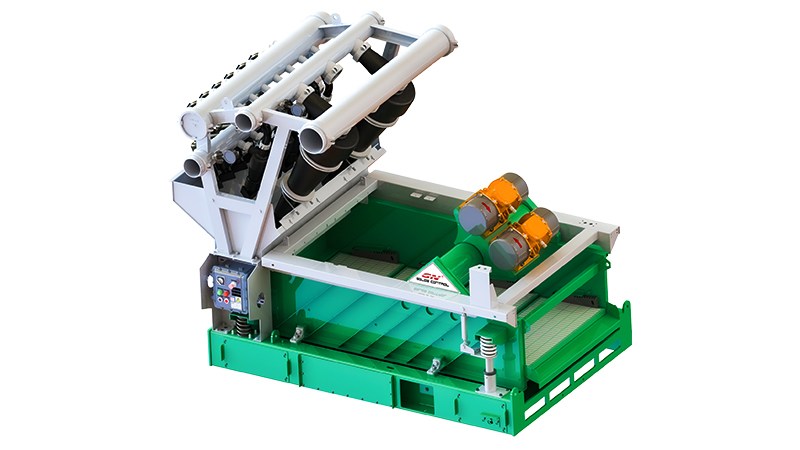

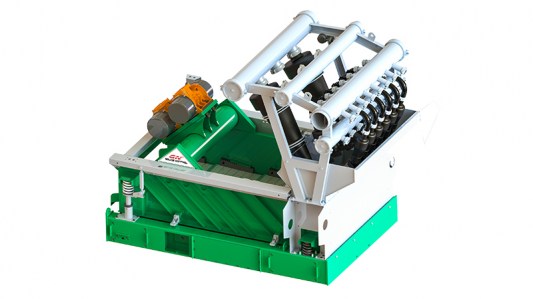

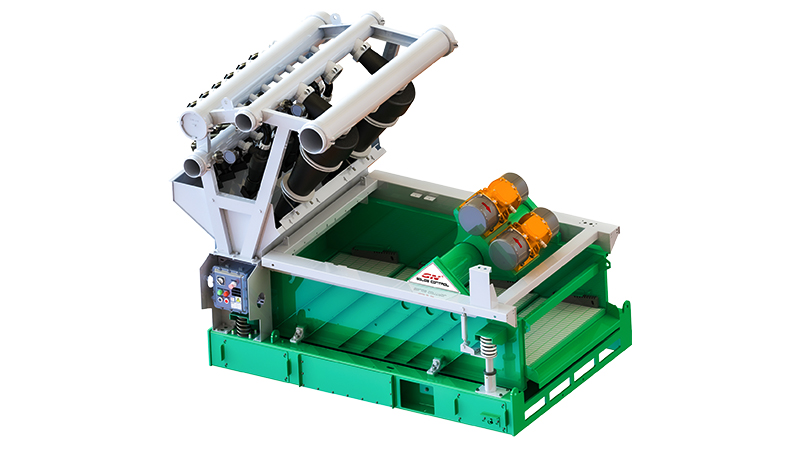

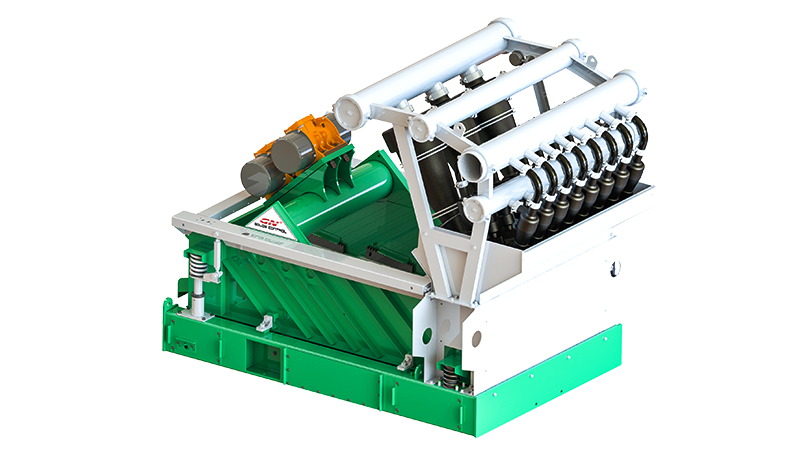

Drilling Mud Cleaner

-

In the oil and gas industry, drilling mud cleaners play a crucial role in the drilling process. These devices are responsible for removing solid particles from drilling fluids, which help maintain the proper viscosity and density of the fluid during operations. The use of a mud cleaner is essential in drilling operations as it ensures the drilling process runs smoothly and efficiently while maintaining the quality of the drilling fluid.

Mud Cleaner Technical Parameter

Model GNZJ594J-S1S8NJ GNZJ594J-S2S12NJ GNZJ594J-S3S16NJ Capacity(m³/h) 120(528GPM) 240(1056GPM) 360(1584GPM) Desander Size(Inch) 10 10 10 Desander Qty(PCS) 1 2 3 Desilter Size(Inch) 4 4 4 Desilter Qty(PCS) 8 12 16 Working Pressure(Mpa) 0.25~0.4 0.25~0.4 0.25~0.4 Inlet Size (Inch) 6 Outlet Size (Inch) 8 Bottom Shaker Specs. Shaker Model GNZS594J GNZJ594J GNZJ594J Vibration Mode Linear Motion Motor(Kw) 2×1.72 Screen Qty(Pcs) 4 4 4 Screen Size: (mm) 585×1165 585×1165 585×1165 Screen Area(m2) 2.73 2.73 2.73 Adjust G Force ≤7.5G ≤7.5G ≤7.5G Vibration Amplitude(mm) 5-7 5-7 5-7 Deck Angle Range -1~+5° EX Standard ExdIIBT4/IECEX/ATEX Weight 1930 2285 2378 Dimension(mm) 2462x2042x2147 2707×2042×2147 2707×2042×2147 The above specification and parameters for reference only. GNZJ Mud Cleaner Features & Benefits

- The entire shaker deck undergoes heat treatment to relieve welding stress, enabling it to withstand high G force.

- The shaker screen is installed with a mechanical ratchet wrench gear for quick tightening, facilitating easy disassembly and ensuring long-lasting durability.

- The wedge blocks for tightening the screen mesh are made of nylon, providing high temperature resistance, corrosion resistance, and wear resistance.

- Vibration motor: Italian OLI brand.

- Polyurethane material is used for sealing between the shale shaker and screen, ensuring a long service life and easy replacement.

- The supporting rubber strips for the bottom frame of the vibration screen are made of stainless steel, offering strong corrosion resistance and a long service life.

- The electrical control box is made of aluminum alloy/stainless steel explosion-proof material, ensuring good sealing and strong corrosion resistance.

- The pre-tensioned shaker screen allows for convenient and quick disassembly and replacement.

- The mud outlet can be switched between bottom and side outlets, accommodating flexible installation on site.

- The angle of the shaker deck can be mechanically adjusted while working at both ends , adapting to different processing capacities.

One of the leading manufacturers of drilling mud cleaners is GN Solids Control, a company that specializes in providing high-quality mud cleaners to the oil and gas industry. GN Solids Control offers a wide range of mud cleaners that are designed to cater to the specific requirements of different industries. Their mud cleaners are known for their compact design, easy installation, and operation.

The GN Solids Control mud cleaner consists of a combination of hydrocyclones and a shale shaker. The hydrocyclones are responsible for separating the solid particles from the drilling fluid, while the shale shaker is used to remove any remaining solids from the fluid. The equipment is designed to handle high flow rates and can effectively remove solids as small as 20 microns.

In addition to their standard mud cleaners, GN Solids Control also offers customized mud cleaners that are designed to meet specific customer requirements. These customized mud cleaners can be tailored to the specific needs of a drilling operation, ensuring maximum efficiency and effectiveness.

The GN Solids Control mud cleaner is designed with safety in mind, and the equipment is fitted with safety features like emergency stop buttons, interlocks, and overload protection, ensuring safe and efficient operation. The device is also designed to reduce noise levels, making it suitable for use in noise-sensitive environments.

GN Solids Control mud cleaners are suitable for various drilling applications, including oil and gas drilling, HDD drilling, and CBM drilling, among others. Their mud cleaners are in high demand due to their high-quality standards, reliability, and cost-effectiveness.

In conclusion, the importance of a drilling mud cleaner cannot be overstated in the oil and gas industry. GN Solids Control provides high-quality mud cleaners that are designed to meet the specific requirements of different industries. Their mud cleaners are easy to install, operate, and maintain, making them a popular choice among drilling companies. Whether you need a standard mud cleaner or a customized solution, GN Solids Control has got you covered.