Welcome to GN Solids Australia

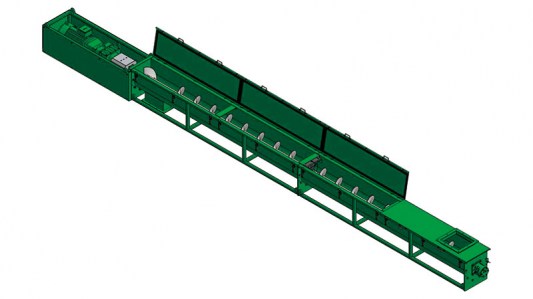

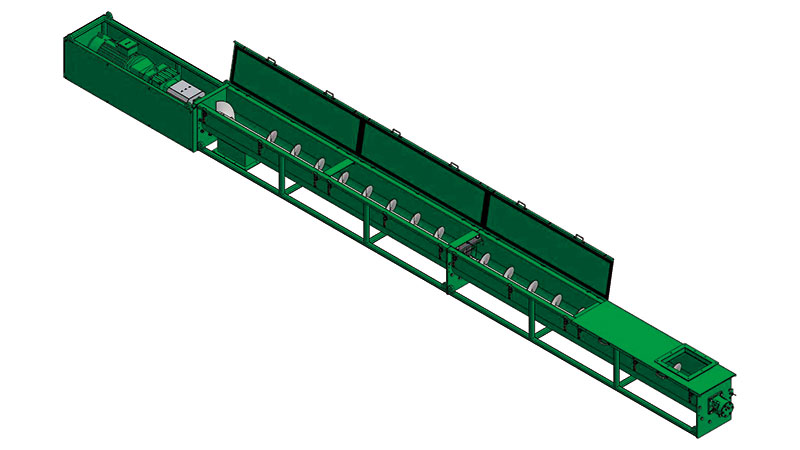

Screw conveyor

Screw conveyor is common material handling device consisting of a screw shaft and screw blades.

-

Screw conveyor is common material handling device consisting of a screw shaft and screw blades. It transports materials by rotating the screw shaft, causing the materials to move along the spiral channel formed by the screw blades. Screw conveyors was wide application in various industries, including grain processing, chemical, mining, construction materials, and environmental engineering.

Gn u-type screw conveyor (auger) technical parameters

Model Screw Diameter

Inch/mmScrew Length

Ft/mCapacity

(Tons/Hour)Motor Power

(Kw)Screw Speed

(Rpm)GNSC10B-24 10/250 24/7.3 15 5.5(7.5HP) 50-70 GNSC10B-36 10/250 36/11 15 5.5(7.5HP) GNSC10B-48 10/250 48/14.6 15 11(15HP) GNSC12B-24 12/315 24/7.3 20 5.5(7.5HP) 50-70 GNSC12B-36 12/315 36/11 20 7.5(10HP) GNSC12B-48 12/315 48/14.6 20 11(15HP) GNSC14B-24 14/350 24/7.3 30 7.5(10HP) 50-70 GNSC14B-36 14/350 36/11 30 11(15HP) GNSC14B-48 14/350 48/14.6 30 15(20HP) GNSC16B-24 16/400 24/7.3 45 11(15HP) 50-70 GNSC16B-36 16/400 36/11 45 15(20HP) GNSC16B-48 16/400 48/14.6 45 18.5(25HP) GNSC18B-24 18/450 24/7.3 55 11(15HP) 50-70 GNSC18B-36 18/450 36/11 55 15(20HP) GNSC18B-48 18/450 48/14.6 55 22 (30HP) Remarks:According to clients requirement, GN Provide customized equipment. The above specification and parameters for reference only.

Screw Conveyor Features:

- High Efficiency: GN Screw conveyors utilize the design of screw augers to provide continuous conveying, enabling swift and efficient transportation of drilling fluid and cuttings from the wellbore to the surface. This helps save time and costs while boosting the overall drilling process efficiency.

- Versatility: GN Screw conveyors can handle various types of materials, including powders, granules, and liquids. This adaptability ensures reliable operation under diverse drilling conditions.

- Space-saving: GN Screw conveyors typically have a small footprint and can be customized to fit different wellbore sizes and ground equipment layouts, optimizing space utilization.

- Ease of Maintenance: With a simple structure and fewer components, screw conveyors have lower maintenance costs. Additionally, the smooth operation of screw augers results in lower failure rates, saving on repair time and expenses.

- Customizable Design: GN Screw conveyors can be custom-designed to meet specific application requirements. Factors such as material properties, flow rate, capacity, and space constraints can be considered during the design process to ensure optimal performance.

- Adjustable Speed and Flow Control Option: GN Screw conveyors often have variable speed drives that allow operators to adjust the conveying speed. This feature enables precise control over the material flow, ensuring efficient and consistent processing.