Welcome to GN Solids Australia

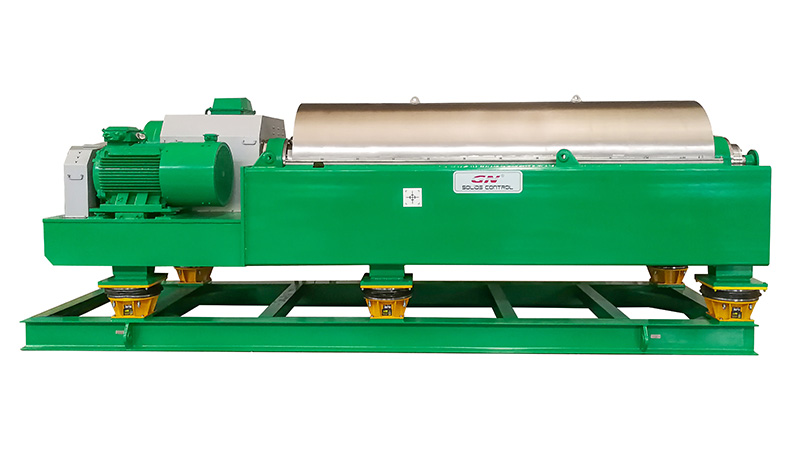

2 Phase Decanter Centrifuge

A 2-phase decanter, also known as a 2-phase centrifuge or a 2-phase separator, is an essential industrial equipment utilized for separating two immiscible phases, typically involving a liquid and a solid.

-

A 2-phase decanter, also known as a 2-phase centrifuge or a 2-phase separator, is an essential industrial equipment utilized for separating two immiscible phases, typically involving a liquid and a solid. It is widely employed across various industries, including oil and gas, chemical, pharmaceutical, and wastewater treatment.

2 Phase GN Decanter Centrifuge Technical Parameters:

Model GNLW-224F GNLW-364F GNLW-454F GNLW-554F GNLW-654E GNLW-764A Bowl Diameter 220 mm

(9 Inch)360 mm

(14 Inch)450 mm

(18 Inch)550 mm

(22 Inch)650 mm

(25.6 Inch)760 mm

(30 Inch)Bowl Length 924 mm

(36.4 Inch)1512 mm

(59.5 Inch)1890 mm

(74.5 Inch)2310 mm

(91 Inch)2730 mm

(82 Inch)3328 mm

(131 Inch)Max Bowl Speed 5099 RPM 3986 RPM 3452 RPM 3123 RPM 2873 RPM 2612 RPM Max G Force 3200 G 3200 G 3000 G 3000 G 3000 G 2900 G L/D Ratio 4.2 4.2 4.2 4.2 4.2 4.4 Main Motor 11 KW 22/30/37 KW 37/45/55 KW 55/90 KW 90/110 KW 110/132/160 KW Back Motor 5.5 KW 7.5/11 KW 11/15/22 KW 15/37/45 KW 18.5/22/37/55 KW 22/37/75/90 KW Beach Angle 8.5° Drive Type VFD+PLC+ HMI Bowl Material SUS2304(Duplex Stainless Steel)/ SUS2205(Duplex Stainless Steel) Centrifugal Casting Screw Material SUS2304(Duplex Stainless Steel)/SUS2205(Duplex Stainless Steel) Remarks - The T-Series,Y-Series,C-Series decanter are interchangeable by replacing bowl assembly.

- Final specifications should be based on commercial and technical offer.

- Customized materials of the decanter centrifuge are available for option.

The above specification and parameters for reference only. Operational Principle:

The decanter functions based on the principle of centrifugal force. The mixture to be separated is introduced into the decanter, where it undergoes acceleration and experiences high centrifugal forces. Consequently, the heavier phase, usually consisting of solid particles, settles at the bottom, while the lighter phase, which is usually the liquid, forms an outer layer.

2 Phase GN Decanter Centrifuge series:

Series/Type Beach Angle Centrifuge Applicable Material Features T Series Dewatering Type 8.5° T series dewatering type decanter centrifuge is usually used to remove liquid from solid phase materials. It is designed for easy separation material include large particle size, high density difference of solid and liquid, low viscosity, high concentration, high treatment capacity and higher dryness than clarity. The materials like sludge or wastewater containing fine particles usually need to be added with flocculants to gather the fine particles condensed into large ones, and then dewatered with T series decanter centrifuge. Y Series Separation Type 15° Y series separation type decanter centrifuge combines the advantages of T series dewatering centrifuge and C series clarifying centrifuge. It is designed not only for the clarity of liquid phase after separation, but also the dryness of solid phase. Y Series separation decanter centrifuge is especially suitable for fine soft material separation. It is usually used in soft materials which are difficult to separate. It suits for material of small particles, small density difference in solid-liquid, large viscosity and small concentration. C Series Clarifying Type 20° C series clarifying type decanter centrifuge is generally used for materials that are difficult to separate, have small particles, small solid-liquid density differences, moderate viscosity, moderate concentration, and require high clarity of clear liquid.

Key Features of GN 2 Phase Decanter Centrifuge:

- Separation of Two Immiscible Phases: The primary function of the 2-phase decanter is to efficiently separate two immiscible phases, typically a liquid and a solid, utilizing the power of centrifugal force.

- Continuous Operation: Designed for continuous operation, these decanters allow a steady feed of the mixture and the uninterrupted discharge of the separated phases. This makes them highly suitable for industrial processes requiring continuous separation.

- High Separation Efficiency:2-phase decanters are renowned for their outstanding separation efficiency. The centrifugal force generated inside the decanter ensures rapid and effective separation of solid particles from the liquid phase.

- Large Processing Capacity: Capable of handling substantial volumes of feed material, these decanters are commonly employed in industries with a need to process significant quantities of mixtures to separate the desired phases.

- Adjustable Parameters: Many 2-phase decanters offer adjustable parameters to optimize the separation process. These parameters include rotational speed, feed rate, liquid level control, and discharge settings. Fine-tuning these parameters allows for precise separation tailored to specific applications.

- Versatile Applications:2-phase GN decanters find wide-ranging applications in various industries, including oil and gas, chemical, pharmaceutical, and wastewater treatment. They are employed for solid-liquid separation, dewatering, clarification, and the recovery of valuable materials.

- Robust Construction:Due to their operation in demanding industrial environments, 2-phase GN decanter centrifuges are constructed using robust materials to withstand continuous operation and handle abrasive or corrosive substances.

- Automation and Control: GN 2-phase decanters come equipped with advanced automation and control systems, allowing for remote monitoring, adjustment of operating parameters, and seamless integration with other process equipment.