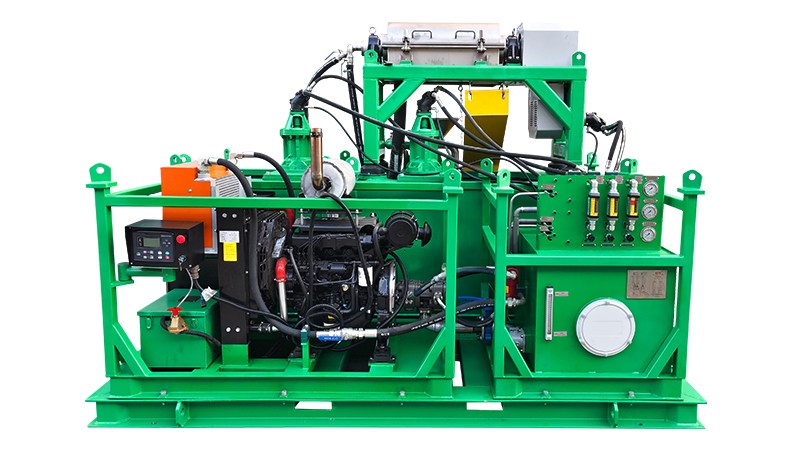

GN Diamond Drilling Solids Removal Unit

-

The GN Compact Diamond Drilling Solids Removal Unit (SRU) is specifically engineered for small mining rigs engaged in diamond drilling or core drilling operations. This unit serves as an alternative to traditional drilling sumps and has gained recognition as a forward-thinking solution within the drilling industry. By employing a closed-loop drilling fluid system, the GN Solids Removal Unit offers a cost-effective approach to minimize environmental impact while significantly enhancing drilling efficiency.

The GN Solids Removal Unit operates on the principle of direct circulation. The drilling fluid is directly pumped from the drill collar to the 2 panels GN Mini Shale Shaker GNZS752 for initial phase solids removal. Subsequently, a positive displacement feeding pump transports the drilling fluid from the shaker tank to the GN 9-inch bowl Mini Decanter Centrifuge for fine solids removal. The clarified drilling fluid is then returned to the drill hole for reuse. Additionally, this highly mobile unit incorporates a mixing chamber, mixing hopper, and pumps to facilitate precise and efficient addition of drilling fluid chemicals. The GNLW224 baby centrifuge, renowned as the world's smallest decanter centrifuge for drilling fluid treatment, enjoys popularity within the diamond core drilling industry.

The GN Compact Diamond Drilling Solids Removal Unit (SRU) is meticulously engineered to cater to small capacity requirements while maintaining a minimal footprint. It excels in the separation of fine solids, offering superior performance for diamond drilling applications.

The bowl of the GN Mini Centrifuge is constructed using SS304, employing centrifugal casting techniques to ensure exceptional durability. To safeguard the screw, Tungsten Carbide Tiles are employed for reliable protection. Additionally, the bowl solids discharge port is fortified with a tungsten casing, and a solids blocking ring is integrated to prevent the accumulation of solids.

The liquid discharge weir height can be easily adjusted to accommodate various application needs, ensuring flexibility and adaptability. During transportation, the bowl assembly is supported by a secure bolts system, providing optimal protection for the bearings. These bearings are sourced from reputable brands such as NSK and FAG, guaranteeing their authenticity and reliability.

In terms of electrical components, the SRU utilizes high-quality components from esteemed brands such as SIEMENS and Schneider. This selection ensures the unit's electrical systems perform at an optimal level, contributing to the overall efficiency and reliability of the SRU.

Parameter:

Model GNSR130D-FHD Capacity 50~130L/Min Cutting Point 2~5 Microns Centrifuge Model GNLW223D-FHD(580Kg) Feeding/discharge Pump 2X GN40ZJL-25-FHD Hopper Model GNSLD-260 Driving Type Diesel+Hydraulic Total Power (kw) 40 Volume (m³) 2.03m³(Feeding Tank 690L, Discharge Tank 1340L) Transport Dimension (mm) L2910X W1950X H2200mm Overall Weight(kg) 2385 Skid (kg) 245 Engine Module (kg) 620 Hydraulic Module (kg) 250 Feeding Tank (kg) 260 Discharge Tank (kg) 430

Key Features and Benefits of the GN Solids Removal Unit:

- Process Capacity: 0-150 LPM (Liters per minute)

- Substantial reduction in drilling fluid consumption (over 40% reduction)

- Self-contained unit comprising integrated components: Shaker, Centrifuge, Pumps, Mixing System, Tanks, and optional Generators

- Environmentally friendly approach with elimination of pit drilling and reduced water consumption

- Reduction in site setup and remediation costs

- Extended lifespan of diamond bits and drill rods, leading to reduced expenses associated with down-hole drilling equipment.