Advanced Pipe Jacking Machines

-

GN Solids is a supplier dedicated to providing high - quality and innovative pipe jacking machines for a wide range of tunneling applications. Our product portfolio includes several advanced series of pipe jacking machines, each designed to meet specific geological and project requirements.

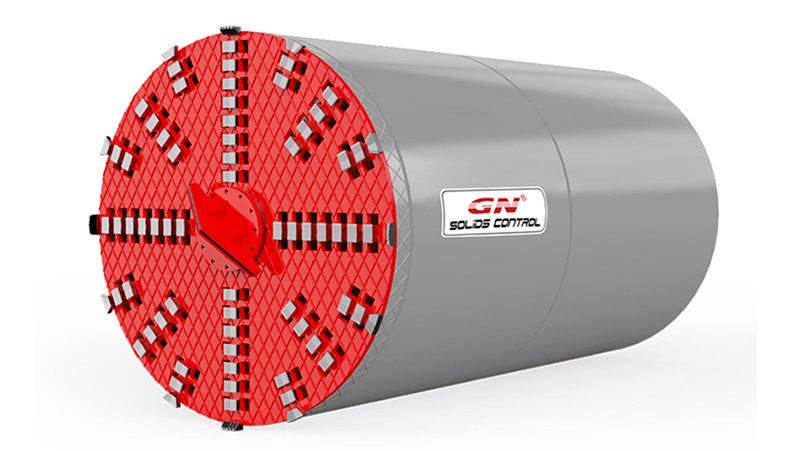

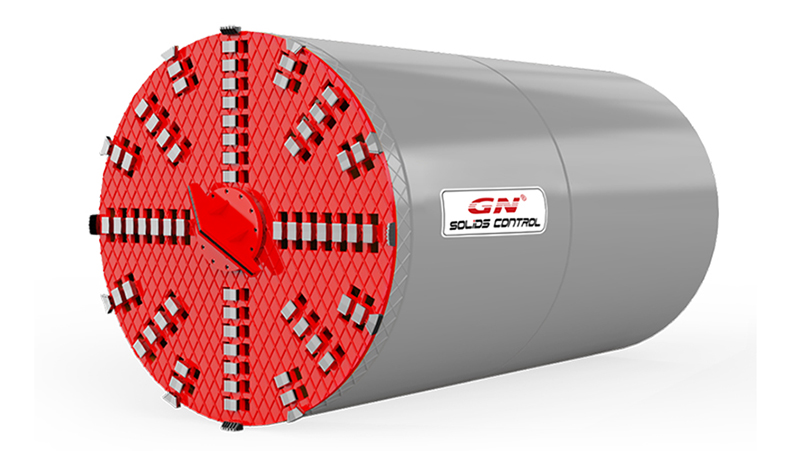

1. SPB Slurry Balance Pipe Jacking Machine Series

1.1 Product Introduction

- Versatile Soil Adaptability: The SPB series is engineered to work in various types of soil. It shows outstanding performance in silty and sand ground conditions, and is especially suitable for strata with a high groundwater level and significant soil quality variations. This adaptability makes it a reliable choice for diverse tunneling projects across the United States and Australia, where different soil types are commonly encountered.

- Stable Excavation and Low Disturbance: During construction, the excavation face remains stable. The machine causes minimal disturbance to the surrounding soil, resulting in extremely low ground settlement. This is crucial for projects in urban areas or near sensitive structures, ensuring the safety and integrity of the surrounding environment.

- Efficient and Continuous Operation: With a highly efficient slurry - based muck transportation system, the machine can operate continuously, achieving a relatively fast jacking speed. This not only improves construction efficiency but also helps to reduce project completion time and costs.

- Safe and Convenient Operation: The SPB series features remote control operation from the ground, while the machine head has a fully automated response system. This setup ensures safe, standardized, and convenient operation, minimizing the risk of accidents and improving the working environment for operators.

- Reliable Sealing and Long Lifespan: The spindle of the machine is equipped with a reliable sealing mechanism, which significantly extends the service life of the equipment. This reduces the need for frequent maintenance and replacement, providing long - term value for our customers.

1.2 Technical Parameters

Inner Dia.Φ(mm) Size(OD ×mm) Power (kW×QTY) Rated Torque(kN×m) Spindle Speed(rpm) Steering Thrust(T×QTY) Slurry Pipe Diameter(mm) 800 980×3600 22×1 40 5.2 38×4 100 1000 1220×3600 22×1 40 5.2 50×4 100 1200 1460×3600 15×2 66 4.3 63×4 100 1500 1820×4080 30×2 220 2.6 80×4 100 1800 2180×4200 22×4 422 1.99 80×4 100 2000 2420×4200 22×4 422 1.99 80×8 100 2200 2660×4200 22×4 422 1.99 80×8 100 2400 2900×4300 30×4 650 1.76 120×8 150 2600 3160×4700 30×5 906 1.58 120×8 150 3000 3580×5400 30×6 1264 1.36 155×8 150 Custom designs are available according to customer requirements.

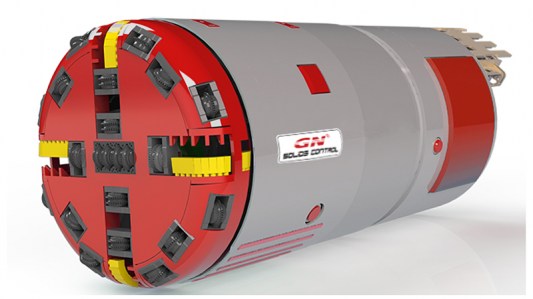

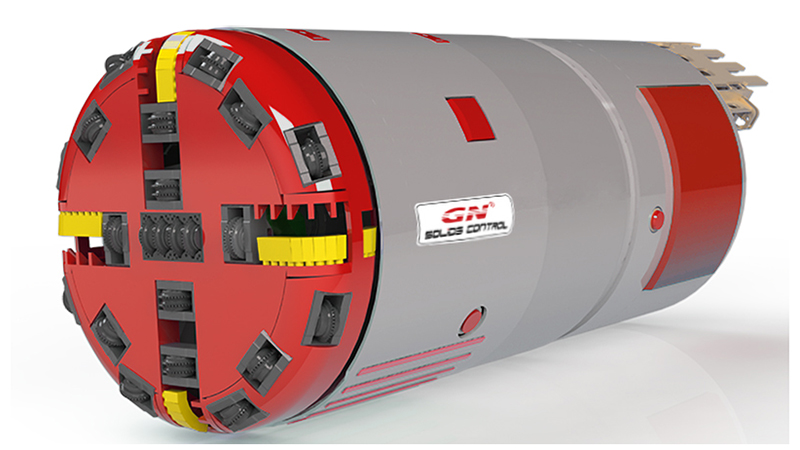

2. HRC Rock Pipe Jacking Machine Series

2.1 Product Introduction

- Broad Geological Adaptability: The HRC series is suitable for a wide variety of geological conditions, including sand, gravel, pebble, boulder, and rock layers. This makes it an excellent choice for tunneling projects in areas of the United States and Australia with complex geological structures.

- Powerful Transmission: It adopts a central spindle drive system, which can generate a large driving torque. This enables the machine to effectively break through hard rock and other tough geological materials during tunneling.

- Efficient Crushing Mechanism: The machine features a two - stage crushing process. The hobbling cutter is used for primary crushing, and the crusher cone is employed for secondary crushing. This dual - stage crushing mechanism improves the efficiency of rock breaking and tunneling.

- Long - Distance Tunneling Capability: The HRC series is capable of long - distance jacking, reducing the need for frequent machine relocation and setup. This is highly beneficial for large - scale tunneling projects, saving both time and resources.

- Advanced Control System: The machine is equipped with a computer - based data collection and control system. This system allows for precise monitoring and control of the tunneling process, ensuring high - quality and reliable tunneling operations.

2.2 Technical Parameters

Inner Dia.Φ(mm) Size(OD ×mm) Power (kW×QTY) Rated Torque (kN×m) Spindle Speed (rpm) Steering Thrust (T×QTY) Slurry Pipe Diameter(mm) 800 980×4400 30×1 57 5 38×4 100 1000 1220×4400 15×3 110 3.9 50×4 100 1200 1460×3800 63×4 123 4 63×4 100 1500 1820×4800 80×4 215 4 80×4 100 1800 2180×5250 30×4 239 4.8 80×4 100 2000 2420×5150 30×4 239 4.8 80×8 150 2200 2660×5200 37×4 404 3.5 80×8 150 2400 2920×5600 37×6 477 3.6 120×8 150 2800 3400×5850 37×6 589 3.6 120×8 150 3000 3580×5910 37×8 589 3.4 155×8 150 Custom designs are available according to customer requirements.

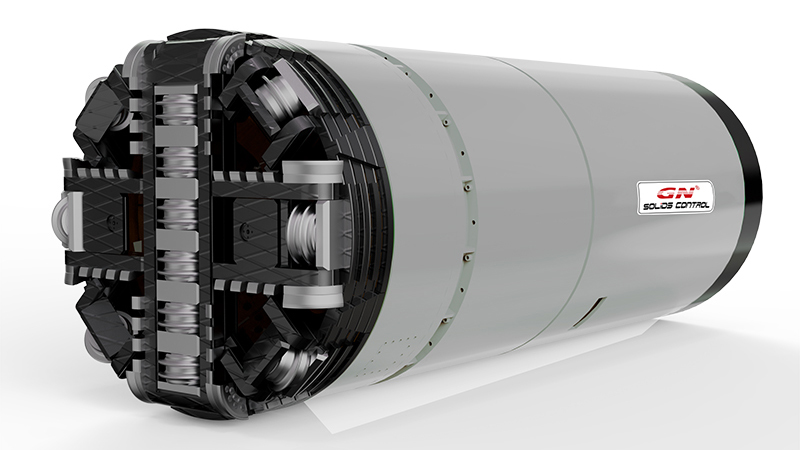

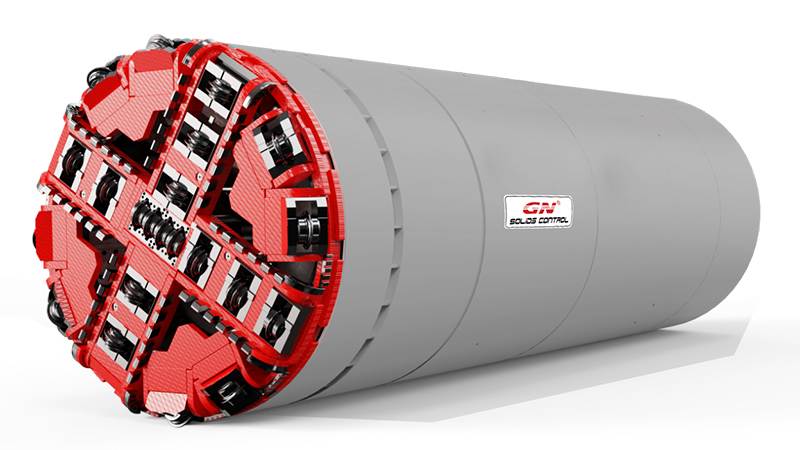

3. Hard Rock Shield Tunnel Boring Machine Series

3.1 Product Introduction

- Exceptional Rock - Breaking Ability: Specifically designed for hard rock formations, this series of machines has a powerful rock - breaking capacity. It can effectively handle tough rocks, making it suitable for tunneling projects in mountainous areas or regions with hard geological strata in the United States and Australia.

- Advanced Technologies: The machines are equipped with high - pressure sealing technology, ensuring reliable operation in high - pressure environments. The main drive reliability technology guarantees stable and long - term operation, while the small - diameter assembly technology enables efficient assembly and disassembly of components, reducing maintenance time and costs.

- Safe and Efficient Cutter Change: The hard - rock shield tunnel boring machines feature an easy - to - use cutter - changing system. This allows for quick and safe cutter replacement during tunneling, minimizing downtime and ensuring continuous and efficient excavation.

- Anti - Mud - Cake Function: The central area of the cutter head is equipped with a scour function. In soft soil layers, this function can prevent the formation of mud cakes on the cutter head, ensuring smooth excavation and maintaining the efficiency of the machine.

3.2 Technical Parameters (Taking GNSPM308A as an Example)

Product Model Inner Diameter of Segment (mm) Outer Diameter of Segment (mm) Segment Length (mm) Total Machine Length (mm) Power Number of Backup Trailers Segment Lifting Method Segment Erector GNSPM308A 3080 3540 1200 53000 8x37kW 5 sets Single beam + double beam Center - rotary Custom designs are available according to customer requirements.

4. Hard Rock Tunnel Boring Machine (TBM)

4.1 Product Introduction

- Efficient Mucking and Self - Excavation: The TBM adopts a belt conveyor mucking system, eliminating the need for pipe segment laying. It can self - excavate in full - face rock formations, improving the tunneling efficiency and reducing construction complexity.

- Tailored for Long - Distance Tunneling: It is equipped with a multi - section shield, a three - dimensional mucking system, and a variable support system. These features are specifically designed to meet the requirements of long - distance hard - rock tunneling, ensuring stable and efficient operation over long distances.

- High - Level Automation: The TBM can be controlled either through centralized control on the ground or local control inside the machine. It has automatic calculation and analysis functions, enabling remote management. This high degree of automation reduces the need for on - site manual operation, improving safety and construction efficiency.

4.2 Technical Parameters (Taking a Typical Model as an Example)

Product Model Excavation Diameter (mm) Total Machine Length (m) Main Drive Power Cutter Type Step Distance (m) Total Thrust (t) Mucking Method Full - Face Hard Rock TBM 4000 72.5 6x45kW Disc cutter 1 800 Downward mucking system Custom designs are available according to customer requirements.

At GN Solids, we are committed to providing our customers in the United States and Australia with the best- in-class pipe jacking machines. Our products are designed with the latest technology, high-quality materials, and strict quality control to ensure reliable performance and long-term value. Contact us today to find the perfect pipe jacking solution for your tunneling project.

Instructions for Ordering Pipe Jacking Machines

1. Pipe - related Details to be Confirmed

When placing an order, our sales team will need to confirm the following details with you:

Standard Pipe Parameters

- Pipe Wall Thickness or Pipe Outer Diameter: Clearly state either the pipe wall thickness or the outer diameter, which is crucial for the design and operation of the equipment.

- Inner Diameter of the Pipe Socket: The inner diameter of the pipe socket is essential for proper connection design.

- Length of the Pipe Socket: Specify the length of the pipe socket to ensure a safe and efficient connection.

Intermediate Jacking Station

If an intermediate jacking station is required, please attach detailed pipe drawings for design and integration.

Steel Pipe Parameters

If steel pipes are used, the following information is also needed:

Inner Diameter: The internal diameter of the steel pipe.

Wall Thickness: The thickness of the steel pipe wall.

Outer Diameter: The external diameter of the steel pipe.

Length: The length of each steel pipe segment.2.Information Needed by the Sales Team

1.Characteristics of Jacking Pipes

Type of Jacking Pipes: Provide the inner diameter, outer diameter, length, and joint form. For non - standard pipes, please attach drawings to determine whether an adapter ring is needed and the stroke of the main jacking cylinder.

2.Dimensions of the Working Shaft and Receiving Shaft

Working Shaft: Provide the depth, length, and width (or diameter).

Receiving Shaft: Provide the length and width (or diameter) to ensure the machine head length is suitable.3.Jacking Distance

Inform the approximate jacking distance for each section (longest, shortest, average) to judge whether an intermediate jacking station is required.

4.Soil Conditions

Soil Composition: Such as clay, silty clay, coarse sand, fine sand, silt, gravel soil, gravel content, maximum gravel size, rock hardness, etc.

Moisture Content: Indicate whether there is abundant groundwater, limited groundwater, or no groundwater for proper equipment selection.5.Surrounding Environment

Inform whether the construction site is in an urban area, suburb, farmland, or involves crossing rivers, railways, highways, etc., to assess construction risks.