Hydrovac Slurry Dewatering System

-

GN specializes in the design and manufacturing of hydrovac slurry processing systems, which are also referred to as slurry dewatering systems or waste slurry management systems. These systems employ liquid and solids separation equipment to effectively treat the soil, soup, or slurry generated from hydrovac or HDD projects. The primary objective is to produce reusable construction materials and discharge clean water by removing contaminants from the slurry.

GN utilizes advanced engineering techniques to develop hydrovac slurry processing systems (Slurry Dewatering Systems) that address the specific requirements of efficient waste slurry management. The system is capable of treating the slurry derived from hydrovac excavation, horizontal directional drilling mud, shield tunnel boring machine slurry, bored piling mud, and other construction slurry waste. By employing liquid and solids separation equipment, such as dewatering vibrating screens, dewatering fine shakers, and dewatering decanter centrifuges, GN effectively separates the different particle sizes present in the slurry. This process results in the recovery of reusable construction materials and the discharge of clean water.

Parameter

System size Small System Big System System Model GNVAC-20A GNVAC-40A Capacity 20 Trucks/Day 40 Trucks/Day Coarse Shaker 1xGNZS594F (2mm)

Screen Area: 29.3 Sq.Ft1xGNZS1236 (2mm)

Screen Area:46.5 Sq.FtFine Shaker 1xGNZS594F (300 microns)

Screen Area:29.3 Sq.Ft1xGNZS706F (300 microns)

Screen Area: 2x50 Sq.FtDesilter with Shaker 1xGNZS594F-8N

Desilter Cones: 8x4inch1xGNZS594F-12N

Desilter Cones:12x4inchDecanter Centrifuge 1xGNLW453C-VFD

Bowl size: 18x61inch1xGNLW553C-VFD

Bowl size: 22x71inchChemical Dosing Unit GNDW-2000 (2000L/Hour), Dosing Pump 2 Sets 2000L/Hour GN Hydrovac Slurry Processing Equipment Features:

- Comprehensive package design ensures turnkey solutions for efficient slurry processing.

- GN's extensive experience in the field substantiates the system's reliability and effectiveness.

- The 5-phase separation system implemented by GN maximizes the efficiency of slurry treatment.

- The modular design of the dewatering system facilitates fast installation and provides flexibility for system relocation.

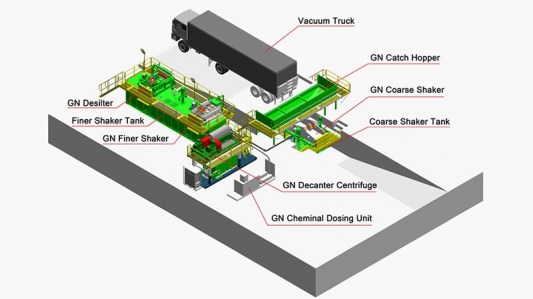

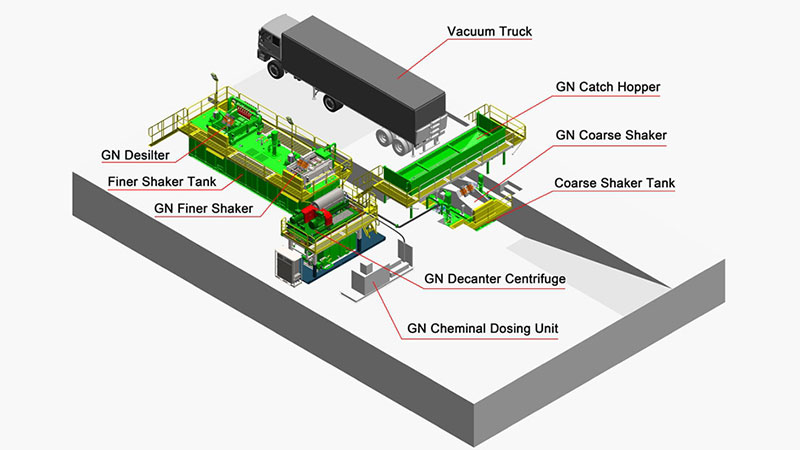

Main Equipment for GN Hydrovac Slurry Processing System:

- Feeding Hopper: Enables the loading of hydrovac truck slurry material into the system.

- Coarse Vibration Screen: Separates coarse materials, eliminating particles larger than the defined threshold from the hydrovac slurry.

- Fine Shaker Module: Processes the fine solids present in the hydrovac slurry waste.

- Desilter Unit: Separates silt particles, incorporating an underflow dewatering screen for enhanced efficiency.

- Dewatering Decanter Centrifuge: Removes ultra-fine solids from the hydrovac mud waste.

- Chemical Dosing System: Facilitates the mixing and supply of polymer chemicals to the dewatering centrifuge for optimal performance.

Introduction to Hydrovac Excavation Slurry Dewatering:

Hydrovac excavation is a non-destructive and precise process that employs pressurized water and a powerful vacuum to simultaneously excavate and evacuate soil. As the pressurized water breaks up the soil, it creates a slurry, which is then extracted into a debris tank using the vacuum system. This non-mechanical excavation method is highly efficient in various soil types, including frozen soil, clay, and hard-packed dirt, as well as in remote or limited-access areas. The waste slurry generated from hydrovac excavation is directed to the hydrovac slurry processing plant, where it undergoes treatment to facilitate water recycling and the recovery of construction materials.

The GN Hydrovac slurry processing system is designed to effectively handle various types of materials, including:

- Soil/soup/slurry (slurry) generated from hydrovac excavation: This refers to the mixture of soil, water, and debris extracted during the hydrovac excavation process.

- Horizontal directional drilling mud: It includes the drilling mud used in horizontal directional drilling operations, which is a method for installing underground utilities and pipelines.

- Shield tunnel boring machine slurry: This pertains to the slurry produced during the operation of shield tunnel boring machines, which are used for tunnel construction.

- Bored piling mud treatment: It involves the treatment of the mud generated during bored piling activities, which is a technique for creating deep foundation elements.

- Other construction slurry waste: The GN Hydrovac slurry processing system can also handle various types of slurry waste generated from construction projects, ensuring effective separation and treatment.