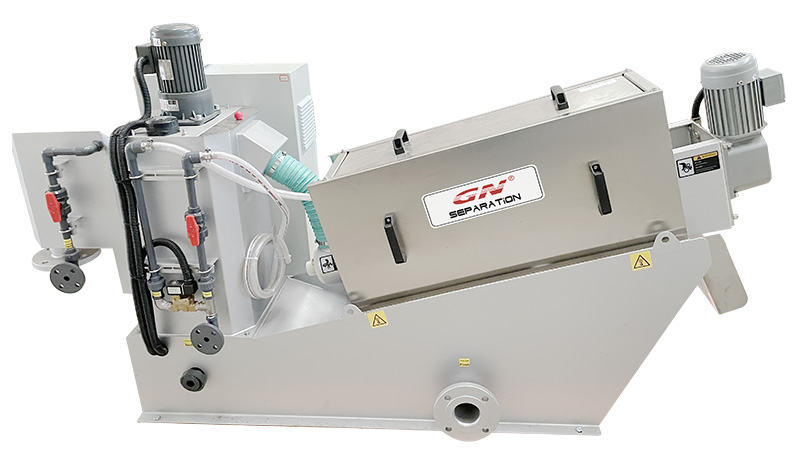

Dewatering Screw Press

-

A dewatering screw press, also known as a screw press dehydrator or screw press separator, is a device used for solid-liquid separation and dewatering of various materials. It is commonly used in industries such as wastewater treatment, food processing, pulp and paper, mining, and agriculture.

The GN screw press sludge dewatering machine represents an economically and environmentally friendly solution for sludge dewatering. Utilizing the principle of screw extrusion, this innovative equipment achieves solid-liquid separation by applying robust squeezing forces through the alteration of screw diameter and pitch, combined with the small gap between the floating ring and fixed ring.

Comprising a fully automatic control cabinet, flocculation modulation box, sludge thickening and dewatering device, as well as a liquid collecting tank, the GN dewatering screw press operates seamlessly. Its advanced automatic control technology enables fully automated flocculation, continuous sludge thickening and squeezing, and ultimately the discharge or return of the collected filtrate liquid.

The GN screw press dewatering machine finds extensive application in sewage treatment projects across various industries, including municipal, aquaculture, food, starch, oil, pharmaceutical, chemical, paper, leather, and more. Its versatility makes it an asset in efficiently handling sludge dewatering needs for different sectors and processes.

Dewatering Screw Press Technical Parameter:

GN SCREW PRESS DEWATERING MACHINE TECHNICAL PARAMETER (FOR CONFIGURATION)

Model DS Standard Capacity

(Absolute Dry Sludge)Capacity for Sludge with Different Concentration 2000mg/L 10000mg/L 20000mg/L 30000mg/L 40000mg/L 50000mg/L 2000mg/L 10000mg/L 20000mg/L 30000mg/L 40000mg/L 50000mg/L GNDL131 4~14 kg/h ~2m³/h ~0.6m³/h ~0.5m³/h ~0.4m³/h ~0.3m³/h ~0.28m³/h GNDL201 8~20 kg/h ~4m³/h ~1.2m³/h ~0.75m³/h ~0.6m³/h ~0.5m³/h ~0.4m³/h GNDL202 16~40 kg/h ~8m³/h ~2.4m³/h ~1.5m³/h ~1.2m³/h ~1m³/h ~0.8m³/h GNDL301 20~70 kg/h ~10m³/h ~3m³/h ~2.5m³/h ~2m³/h ~1.5m³/h ~1.4m³/h GNDL302 40~140 kg/h ~20m³/h ~6m³/h ~5m³/h ~4m³/h ~3m³/h ~2.8m³/h GNDL303 60~210 kg/h ~30m³/h ~9m³/h ~7.5m³/h ~6m³/h ~4.5m³/h ~4.2m³/h GNDL401 67.5~160 kg/h ~33.7m³/h ~10m³/h ~6.5m³/h ~5m³/h ~4m³/h ~3.2m³/h GNDL402 135~320 kg/h ~67.5m³/h ~20m³/h ~13m³/h ~10m³/h ~8m³/h ~6.4m³/h GNDL403 200~480 kg/h ~100m³/h ~30m³/h ~19.5m³/h ~15m³/h ~12m³/h ~9.6m³/h GNDL404 266~640 kg/h ~133m³/h ~40m³/h ~26m³/h ~20m³/h ~16m³/h ~12.8m³/h The above specification and parameters for reference only. GN SCREW PRESS DEWATERING MACHINE TECHNICAL PARAMETER (FOR CAPACITY)

Model Screw Diameter Screw Qty Screw Power Agitator Power Total Power Flushing Pressure Flushing Water (L/H) Weight|(KG) GNDL131 130mm 1 0.2KW 0.2KW 0.4KW 0.1Mpa-0.2Mpa

(No high pressure flushing device is required)20 205 GNDL201 200mm 1 0.37KW 0.2KW 0.57KW 30 290 GNDL202 2 0.74KW 0.2KW 0.94KW 30 470 GNDL301 300mm 1 0.55KW 0.4KW 0.95KW 40 820 GNDL302 2 1.1KW 0.55KW 1.65KW 80 1350 GNDL303 3 1.65KW 0.55KW 2.2KW 120 1820 GNDL401 400 1 1.1KW 0.55KW 1.65KW 70 1990 GNDL402 2 3KW 0.75KW 3.75KW 140 3310 GNDL403 3 4.5KW 1.1KW 5.6KW 210 4380 GNDL404 4 6KW 0.75KWx2 7.5KW 280 6170 The above specification and parameters for reference only.

BENEFITS OF SCREW PRESS DEWATERING MACHINE

- Versatile Applications: The screw press dewatering machine is capable of efficiently dewatering a wide range of sludge types, including oily sludge, making it highly adaptable for various treatment needs.

- Continuous and Uninterrupted Operation: With its automatic operation, the machine runs continuously, minimizing the risk of blockages and ensuring a smooth dewatering process.

- Cost-Effective Solution: The screw press offers low investment and operation costs, and it eliminates the need for additional treatments, preventing secondary pollution, which further contributes to cost savings.

- Environmentally Friendly and Energy Efficient: Its compact design and small footprint reduce energy consumption, making it an eco-friendly choice for sludge dewatering.

- Phosphorus Release Prevention: Unlike anaerobic sludge dewatering, the screw press allows dewatering under aerobic conditions, effectively preventing phosphorus release and promoting a more sustainable process.