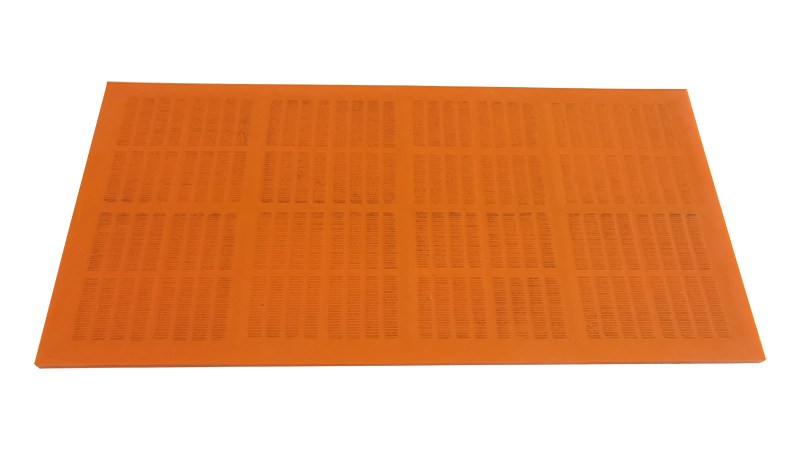

Polyurethane Screen Panel

-

Polyurethane Screen Panel are an innovative type of screen panel made from advanced polymer materials and are widely utilised for solid-liquid separation and screening operations in industries such as Mining, petrochemical, and food. These panels are crafted from polyurethane material using specialised processing techniques, resulting in a compact composition. They exhibit exceptional resistance to corrosion, wear, and aging. Compared to traditional metal screen panels, polyurethane rigid screen panels demonstrate superior shock resistance, elasticity, and damping effects, effectively safeguarding against deformation and fatigue cracks. Embodying a diverse range of aperture shapes, such as rectangular, circular, and elliptical, they cater to diverse separation and screening requirements, thereby achieving enhanced screening outcomes. Additionally, polyurethane rigid screen panels are effortlessly installed, dismantled, and facilitate routine maintenance and cleaning, ultimately promoting heightened production efficiency and product quality.

Common Opening Size Of Gn Polyurethane Screen Panel

Opening Size(MM) Standard Type Efficiency type Lifetime Type Screen bar diameter (MM) Opening rate (%) Screen bar diameter (MM) Opening rate (%) Screen bar diameter (MM) Opening rate (%) 8 4 14 3 53 6 33 10 4 51 3 59 6 39 12 6 44 4 56 8 36 14 6 49 4 60 8 40 16 6 53 4 64 8 44 18 7 52 6 56 10 41 20 7 55 6 59 10 44 22 8 54 6 62 10 47 24 10 50 8 56 12 44 27 12 48 10 53 12 48 30 12 51 10 56 12 51 The above specification and parameters for reference only.

Technical Characteristics Of Gn Polyurethane Screen Panel

- Polyurethane Screen Panels are widely used in vibrating screening machines due to their high strength, elasticity, wear resistance, and excellent permeability. These characteristics make them suitable for material screening operations in various fields, including mining, construction materials, metallurgy, chemical, and environmental protection.

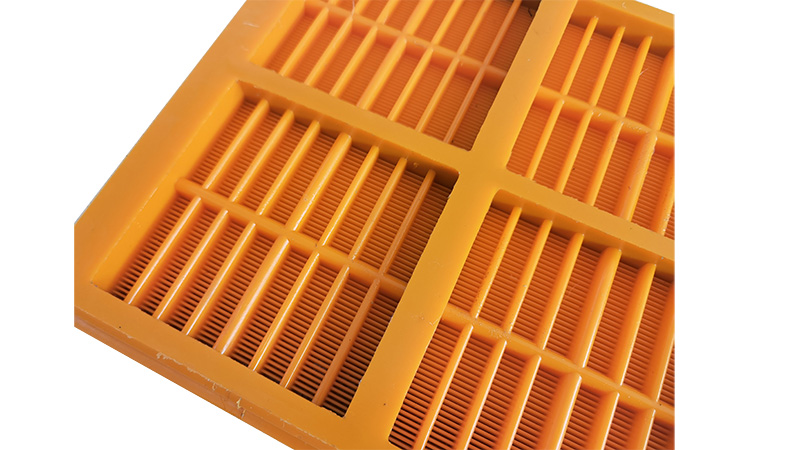

- The manufacturing process of Polyurethane Screen Panels involves a specialised approach. Polyurethane raw materials, fillers, modifiers, and other substances are blended, injected into molds, and subjected to heating, pressing, and demolding processes. This results in the production of complex screening components such as screen panels and screen cylinders. The surface of Polyurethane Screen Panels is typically made of polyurethane plastic, which exhibits exceptional wear resistance and strong antioxidation capabilities, enhancing both durability and efficiency. Reinforcing parts utilise polyester resin composite reinforcement to increase the strength and toughness of the screen panels. Moreover, this material possesses shock-absorbing and buffering properties, effectively reducing vibrations and noise during the operation of vibrating screening machines.

- Polyurethane Screen Panels offer numerous advantages, including excellent sealing performance, wear resistance, prolonged lifespan, lightweight structure, and user-friendly operation. Furthermore, this material extends the service life of vibrating screen machines and reduces overall system noise, making it a superior choice for screen panel materials. However, it is essential to carefully select the appropriate thickness and mesh size of Polyurethane Screen Panels to prevent premature wear when using them in vibrating screen machines. Additionally, GN has the capability to adjust the hardness and material of the Polyurethane Screen Panels according to specific user requirements, ensuring they meet the screening demands of different industries and materials.