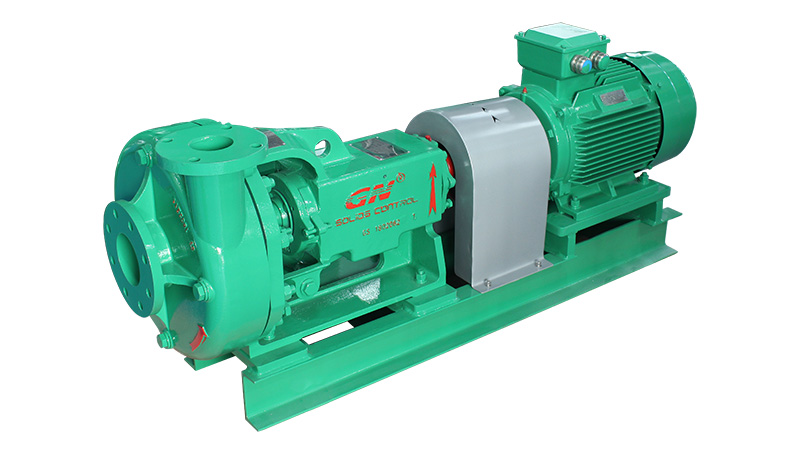

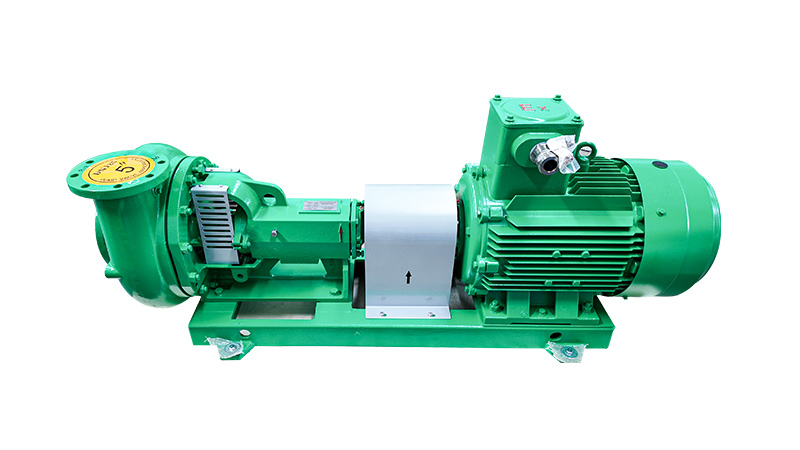

Centrifugal Pump

-

A centrifugal pump is a type of mechanical device that is used to transfer fluids by converting rotational kinetic energy to hydrodynamic energy. This type of pump is widely used in various industrial and domestic applications to move liquids from one location to another.

GN Centrifugal Pump Specifications

Model Flow(m³/h) Lift(m) Power(Kw) Motor Speed(RPM) Impeller(Inch) GNSB8×6C-13J 320m3/h 35m 75kW 1450RPM(50Hz) 13in GNSB8×6C-11J 1750RPM(60Hz) 11in GNSB8×6C-12J 272m3/h 35m 55kW 1450RPM(50Hz) 12in GNSB8×6C-10J 1750RPM(60Hz) 10in GNSB6×5C-12J 200m3/h 35m 45kW 1450RPM(50Hz) 12in GNSB6×5C-10J 1750RPM(60Hz) 10in GNSB6×5C-11J 150m3/h 30m 37kW 1450RPM(50Hz) 11in GNSB6×5C-9.5J 1750RPM(60Hz) 9.5in GNSB5×4C-12J 120m3/h 35m 30kW 1450RPM(50Hz) 12in GNSB5×4C-10.5J 1750RPM(60Hz) 10.5in GNSB5×4C-11J 90m3/h 30m 22kW 1450RPM(50Hz) 11in GNSB5×4C-9.5J 1750RPM(60Hz) 9.5in GNSB4×3C-11J 65m3/h 35m 18.5kW 1450RPM(50Hz) 11in GNSB4×3C-10J 1750RPM(60Hz) 10in GNSB4×3C-10J 55m3/h 28m 15kW 1450RPM(50Hz) 10in GNSB4×3C-9.5J 1750RPM(60Hz) 9.5in GNSB4×3C-9.5J 45m3/h 25m 11kW 1450RPM(50Hz) 9.5in GNSB4×3C-9J 1750RPM(60Hz) 9in GNSB3×2C-9J 35m3/h 35m 7.5kW 1450RPM(50Hz) 9in GNSB3×2C-8J 1750RPM(60Hz) 8in The above specification and parameters for reference only. Centrifugal pumps are commonly used in various industries, such as the oil and gas industry, where they are used to transfer drilling mud and other fluids between different stages of the drilling process. In addition, they are widely used in wastewater treatment plants, chemical processing facilities, and many other industries.

The centrifugal pump works by using a rotating impeller to create a flow of fluid. The impeller generates centrifugal force, which drives the fluid towards the outer edge of the pump casing. As the fluid moves towards the outlet of the pump, it gains kinetic energy and exits at a high velocity.

When selecting a centrifugal pump, several factors need to be considered, including flow rate, head pressure, and the type of fluid being pumped. The pump should be designed to handle the specific properties of the fluid, including its viscosity, temperature, and corrosiveness. For instance, if the fluid is highly viscous, a pump with a larger impeller diameter or slower rotation speed may be required.

Moreover, there are different types of centrifugal pumps available, including end-suction pumps, inline pumps, and self-priming pumps. Each type of pump has its own unique features and benefits, and the selection of the pump type depends on the specific application.

In conclusion, centrifugal pumps are an essential component in many industrial and domestic applications. Their ability to transfer fluids quickly and efficiently makes them a valuable tool for a wide range of industries. The proper selection and maintenance of centrifugal pumps can result in increased efficiency, reduced downtime, and cost savings.