GN Solids Control has recently completed a significant sale of its advanced mud tank system tailored for workover drilling rigs in Africa. This system is designed to enhance drilling efficiency and safety in challenging environments, meeting rigorous ATEX standards.

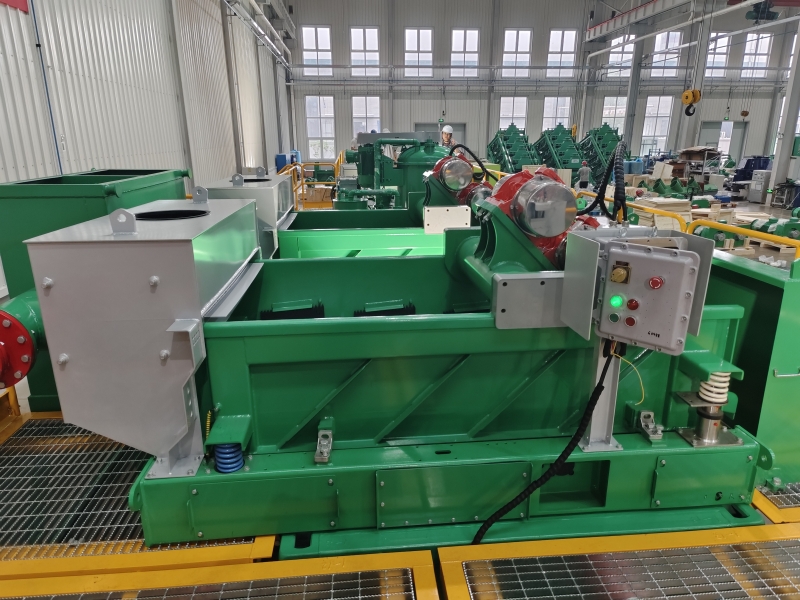

The system features two GNZS594J-SHBJ shale shakers, equipped with high-capacity screens to efficiently separate drill cuttings from the drilling fluid. These shakerss are integral to maintaining fluid quality and optimizing the drilling process. Accompanying the shakers are a vacuum degasser, which removes gas from the mud to prevent the formation of dangerous gas pockets, and a poorboy degasser, which further ensures gas-free drilling fluid.

Four agitators are included in the system to ensure proper mixing and homogenisation of the drilling fluid, crucial for maintaining optimal fluid properties throughout the drilling operation. The system also incorporates two centrifugal pumps for efficient fluid transfer and a mud jet mixer to enhance the mixing process.

The package is completed with three specialised mud tanks: one for the supply of mud, one for the shale shaker, and one for the jet mixing process. These tanks are designed with robust construction to withstand the harsh conditions typical of workover drilling operations.

The ATEX certification ensures that all units are suitable for use in potentially explosive environments, providing an additional layer of safety. This certification is essential for operations in Africa, where the risk of encountering hazardous gases is significant.

GN Solids Control's mud tank system not only meets the high safety and operational standards required for workover drilling but also delivers reliability and efficiency, contributing to smoother and more cost-effective drilling operations.

For more details about the products and their specifications, visit GN Solids Control's website here.