GN Solids Control has recently delivered a 3000HP drilling rig solids control system to an Asian drilling company, enhancing their drilling mud treatment process with a comprehensive suite of specialised equipment.

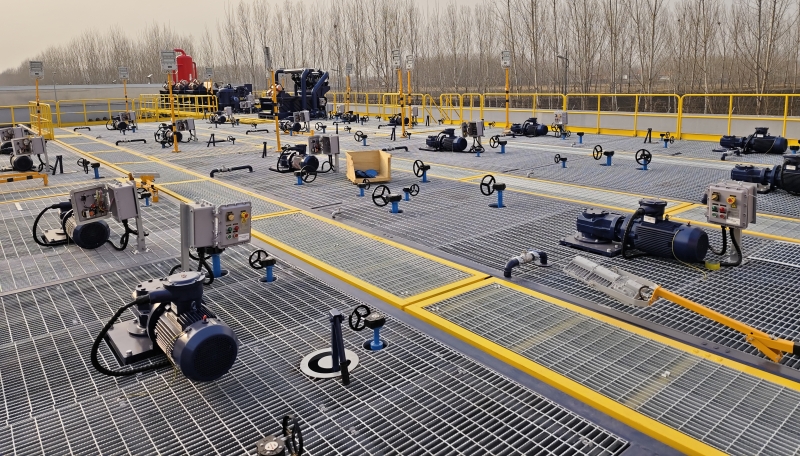

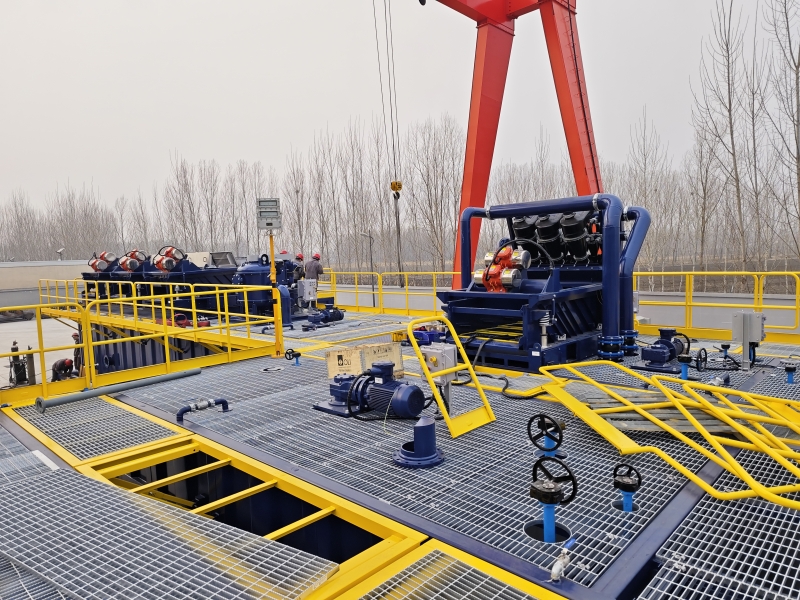

The system includes a range of components designed to improve the efficiency and reliability of solids control. Central to the process is the GNZS596K shale shaker, responsible for removing large cuttings from the drilling mud. Following this, the mud cleaner integrates multiple desander and desilter hydrocyclones with a fine-screen shaker to target smaller particles, ensuring thorough separation.

Gas entrapped in the mud is managed by the GNZCQ-270B vacuum degasser, preventing disruptions in downstream equipment. Meanwhile, the GNZYQ1200A mud gas separator handles larger gas volumes, ensuring safe operations by venting harmful gases. To maintain optimal flow, the centrifugal pump transports the treated mud efficiently across the system.

Supporting these primary functions, the mud agitator prevents solids from settling in the mud tanks, ensuring a consistent mixture. The mud gun further aids in keeping tank corners clean and preventing build-up. To replenish and condition the drilling fluid, the jet mud mixer accurately combines additives into the circulating system.

This integrated solids control system delivers notable operational benefits, including improved drilling efficiency, reduced equipment wear, and enhanced safety by minimising gas-related risks. The delivered equipment is designed with durability and ease of maintenance in mind, meeting the demanding conditions of high-powered drilling rigs.

By equipping their rig with GN Solids Control’s robust system, the Asian drilling company is set to achieve more stable drilling performance and prolonged equipment lifespan, optimising their overall project efficiency.

GN Solids Control remains committed to delivering reliable solids control solutions tailored to diverse drilling environments, ensuring clients benefit from effective mud treatment and improved operational control.