Welcome to GN Solids Australia

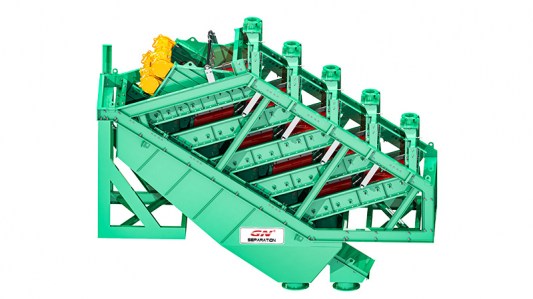

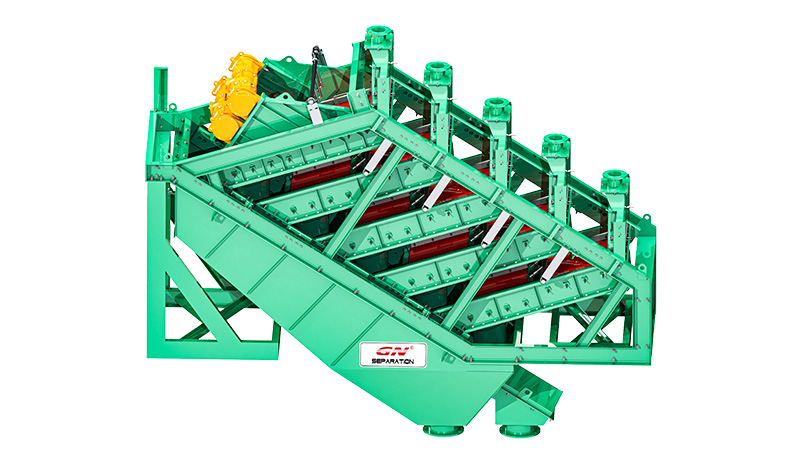

Stack Vibrating Screen - Fine Sizer

The Stack Vibrating Screen is an efficient advancement in vibrating screen technology.

-

The Stack Vibrating Screen is an efficient advancement in vibrating screen technology. It allows for multiple layers of screening on the same screen, improving efficiency in the mining industry. The structure and working principle of the layered mining vibrating screen are as follows:

Stack Vibrating Screen-Fine Sizer - Small And Medium Size Models Technical Parameters

Model GND3Z 1014 GND4Z 1014 GND5Z 1014 GND2Z 1021 GND3Z 1021 GND4Z 1021 GND5Z 1021 Screen box layers 3 4 5 2 3 4 5 Total screening area 4.2㎡ 5.6㎡ 7㎡ 4.2㎡ 6.3㎡ 8.4㎡ 10.5㎡ Linear vibration amplitude (double) 1-2mm Total installed power (output) 2sets×1.84kW Vibration frequency 25Hz Screen inclination 17.5° Mesh size 0.045- 2mm Screen size (L×W) 700×1050(mm) Number of screen 6 8 10 6 9 12 15 Processing capacity (Dry ore m3/h) 6~18 8~24 10~30 5~12 6~19 8~25 10~32 Remark - The above parameters are for reference only and can be adjusted according to the customer's situation. Finally the quotation and technical agreement shall prevail.

- Regarding Stack Vibrating Screens of the same size for different material requirements under different working conditions, the processing capacity varies greatly. For details, please consult GN.

The above specification and parameters for reference only. Stack Vibrating Screen-Fine Sizer - Medium And Large Size Model Technical Parameters

Model GND3Z1416 GND4Z1416 GND5Z1416 Screen box layers 3 4 5 Total screening area 6.72㎡ 8.96㎡ 11.2㎡ Linear vibration amplitude (double) 1-2mm Total installed power (output) 2sets×1.84kW 2sets×2.3kW Vibration frequency 25Hz Screen inclination 17.5° Mesh size 0.045- 2mm Screen size (L×W) 840×1450(mm) Number of screen 6 8 10 Processing capacity (Dry ore m3/h) 8 ~ 25 11~33 14~42 Remark - The above parameters are for reference only and can be adjusted according to the customer's situation. Finally the quotation and technical agreement shall prevail.

- Regarding Stack Vibrating Screens of the same size for different material requirements under different working conditions, the processing capacity varies greatly. For details, please consult GN.

The above specification and parameters for reference only.

Stack Vibrating Screen-Fine Sizer Features

- The Stack Vibrating Screen-Fine Sizer is a versatile and efficient vibrating screen designed for precise material classification. Its structure comprises a frame, screen box, screen, vibrator, and self-cleaning device. With its multi-layered screening structure, typically consisting of three or even more layers, each layer's screen mesh aperture can be adjusted from large to small, allowing for coarse, medium-coarse, and fine screening of materials with accuracy and efficiency.

- Widely used in mining, metallurgy, and construction materials industries, especially in applications that demand high precision screening, the Stack Vibrating Screen offers numerous advantages. It boasts high screening efficiency, large throughput capacity, and easy maintenance.

- Compared to conventional single-layer vibrating screens, the Stack Vibrating Screen-Fine Sizer utilises multiple layers of screen surfaces, achieving efficient material screening within a compact footprint. This design reduces space occupation and equipment weight while enhancing screening efficiency and accommodating diverse screening requirements for mineral materials.

- In the mining industry, the Stack Vibrating Screen finds extensive use for grading, screening, dust removal, and other operations involving various ores, coal, and construction materials. It excels in providing high classification precision, screening efficiency, compact structure, small footprint, and the ability to screen both liquids and solids. Undoubtedly, it stands as an indispensable vibrating screening equipment for the mining industry.