Shale Shaker Screen

-

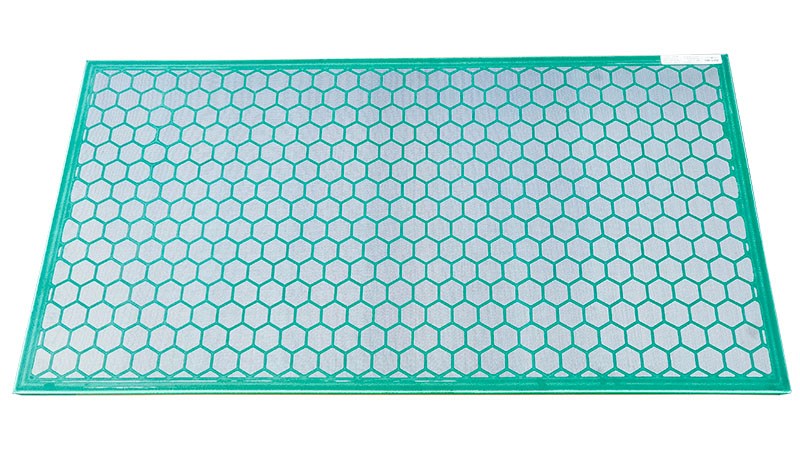

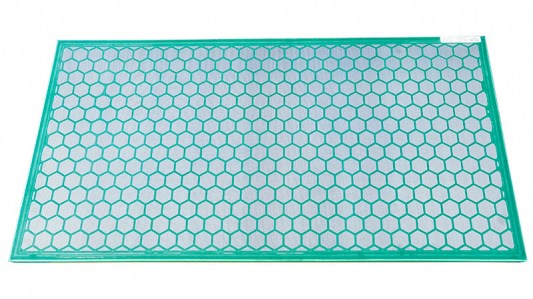

GN Shaker Screen is a critical component of GN Solids Control's shale shaker system. The GN Shaker Screen is designed to fit all standard shale shakers and is manufactured to the highest standards using quality materials. It is a vital component of the solid control system, and it plays a crucial role in separating solids from drilling mud.

The GN Shaker Screen is built to withstand harsh operating conditions and is corrosion-resistant. It is made of high-quality stainless steel wire mesh and has a large effective screen area, making it efficient at separating solids from drilling mud. The shaker screen is easy to install and maintain, which saves time and money.

Features of GN Shaker Screen

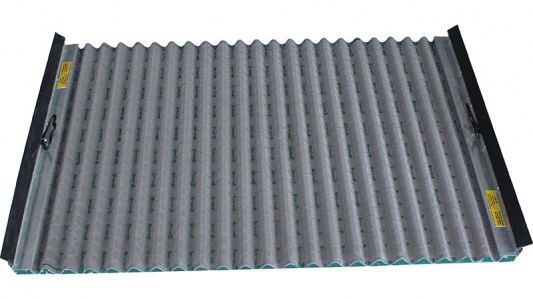

- High G-force capacity: The GN Shaker Screen has a high G-force capacity, which enables it to separate solids from drilling mud effectively. It can handle large volumes of drilling mud and solids, making it ideal for use in drilling operations.

- Corrosion-resistant: The GN Shaker Screen is built to withstand harsh operating conditions, and it is corrosion-resistant. It can withstand exposure to saltwater and other corrosive materials, making it ideal for use in offshore drilling operations.

- High-quality stainless steel wire mesh: The shaker screen is made of high-quality stainless steel wire mesh, which is durable and long-lasting. The wire mesh is tightly woven, which ensures that it can withstand the high G-forces generated during the separation process.

- Large effective screen area: The GN Shaker Screen has a large effective screen area, which enables it to handle large volumes of drilling mud and solids. The large screen area also ensures that the shaker screen can separate solids from drilling mud efficiently.

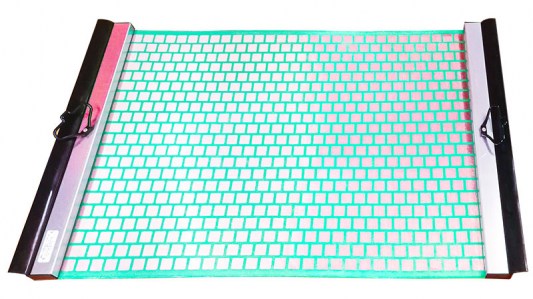

- Easy to install and maintain: The shaker screen is easy to install and maintain, which saves time and money. It can be easily replaced when worn out or damaged, which ensures that the solid control system runs smoothly.

Benefits of using GN Shaker Screen

- Efficiently separates solids from drilling mud: The GN Shaker Screen is designed to separate solids from drilling mud efficiently. This helps to reduce the amount of drilling mud required, which saves money and reduces waste.

- Reduces the amount of drilling mud required: The shaker screen can separate solids from drilling mud efficiently, which reduces the amount of drilling mud required. This helps to reduce the cost of drilling operations and minimizes waste.

- Extends the life of downstream equipment: The GN Shaker Screen plays a crucial role in protecting downstream equipment from damage caused by solids in the drilling mud. This helps to extend the life of downstream equipment, which saves money in the long run.

- Increases drilling efficiency: The shaker screen helps to increase drilling efficiency by separating solids from drilling mud quickly and efficiently. This helps to reduce downtime and increase productivity.

- Reduces waste disposal costs: The GN Shaker Screen helps to reduce waste disposal costs by separating solids from drilling mud efficiently. This reduces the amount of waste that needs to be disposed of, which saves money.

Types of GN Shaker Screen

GN Solids Control offers a wide range of shaker screen types to suit different drilling conditions. These include:

- Steel Frame Shaker Screen: The steel frame shaker screen is made of high-quality steel and is designed to withstand harsh operating conditions.

- Composite Frame Shaker Screen: The composite frame shaker screen is made of a combination of plastic and metal and is corrosion-resistant.

- Hookstrip Shaker Screen: The hookstrip shaker screen is designed to be quick and easy to install and replace.

- Pyramid Shaker Screen: The pyramid shaker screen is designed to handle high volumes of drilling mud and solids.

- Pinnacle Shaker Screen: The pinnacle shaker screen is designed to handle high volumes of drilling mud and is corrosion-resistant.

- FLC 500 Shaker Screen: The FLC 500 shaker screen is designed to fit the FLC 500 series shale shakers.

- FLC 2000 Shaker Screen: The FLC 2000 shaker screen is designed to fit the FLC 2000 series shale shakers.

- Mongoose Shaker Screen: The mongoose shaker screen is designed to fit the Mongoose series shale shakers.

Conclusion

GN Shaker Screen is a high-quality and efficient solution for separating solids from drilling mud. With its corrosion-resistant construction, large effective screen area, and easy installation and maintenance, it is the perfect choice for drilling operations in a variety of conditions. Choose GN Shaker Screen for increased drilling efficiency, reduced waste disposal costs, and extended equipment life. With a wide range of shaker screen types to choose from, GN Solids Control can provide the perfect solution for your drilling needs.