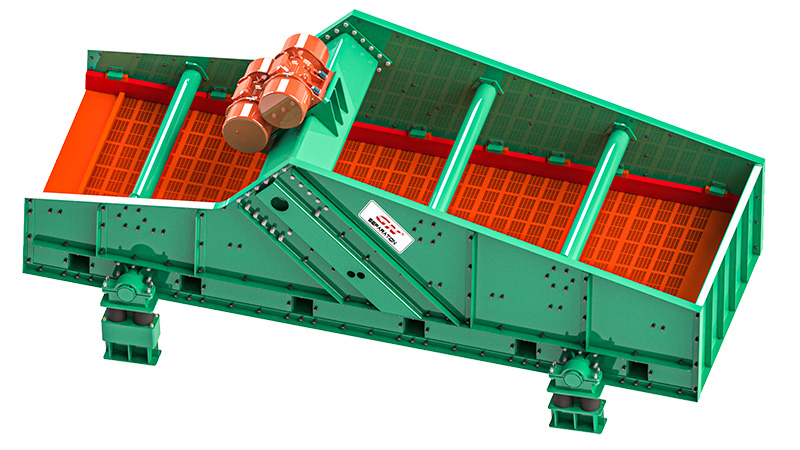

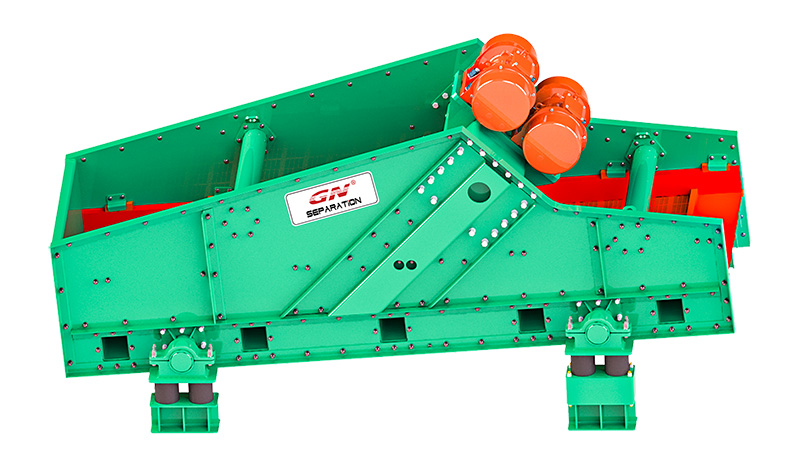

Classification Linear Vibrating Screen

-

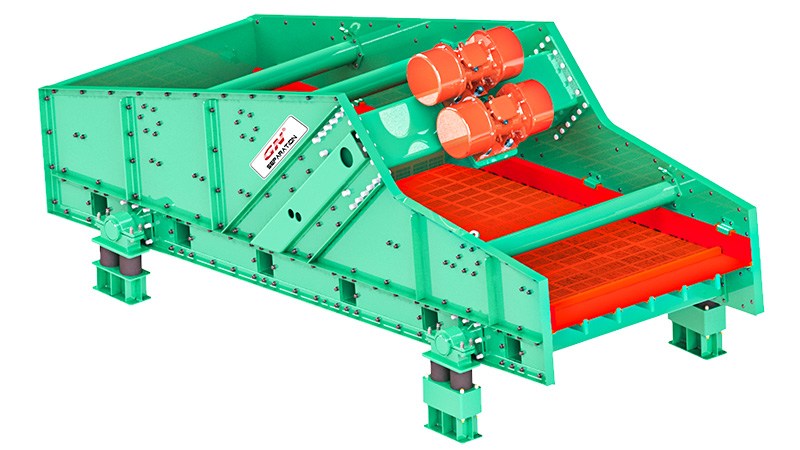

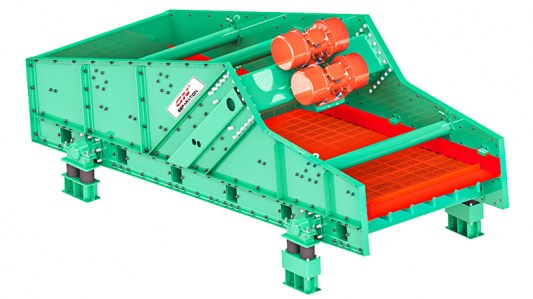

GN Classification Vibrating Screen is extensively utilized for the classification and screening of materials such as iron ore, coal, non-ferrous metal ore, building materials, and chemicals. Employing advanced design methodologies like finite element analysis and anti-fatigue analysis, the equipment ensures a well-structured, energy-efficient, and high-capacity screening process. It excels in challenging working conditions prone to corrosion and wear, offering exceptional processing capacity, efficiency, and stability. The screen size can be customized as per customer requirements.

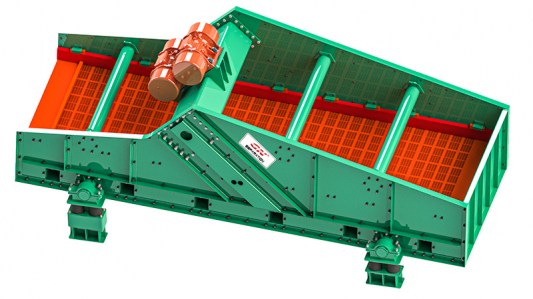

The screen features two vibrating motors, inducing linear movement of the screen body through reverse self-synchronization. This motion drives the screen panel to vibrate synchronously, enabling effective material layering and grading based on specified particle sizes. The materials are continuously buffered, screened, and graded, with the upper and lower portions being discharged into respective troughs for further processing. The angle between the vibration force direction and the horizontal axis can be tailored to optimize processing capacity based on material properties.

Technical Characteristics & Advantages of the Linear Motion Classification Vibrating Screen:

- Non-welded Wallboard: The wallboard is constructed using steel plates with enhanced impact toughness and cold bending properties. Hydraulic tension assembly with imported HUCK rivets avoids welding-related residual stress and material defects, ensuring fatigue strength.

- Finite Element Analysis: Through finite element analysis, the structural strength and vibration quality are optimized, reducing stress and extending equipment lifespan.

- Corrosion and Wear Resistance: Fluids touching and easily worn parts are treated with polyurea spray from the USA, providing resistance to corrosion, erosion, and wear.

- Post Weld Heat Treatment: Main components undergo post weld heat treatment to effectively eliminate welding stress.

- Product Serialization: The screen is designed to meet varying process conditions for different customers, and the modular polyurethane screen panel allows for versatile and convenient replacement.

- Adjustable Inclination: The screen is installed at a positive inclination angle with a 4-degree adjustable option, accommodating different process material requirements.

- Plane Design: The whole screen surface is flat, enhancing material screening and grading efficiency, and maximizing the effective screening area.

- Rubber Damping Spring: The rubber damping spring design offers advantages such as effective damping, low noise, minimal resonance, good resilience, stable mechanical performance, long service life, and cost-effectiveness.

Classification Vibrating Screen Technical Parameter:

Model GNLMP1236 GNLMP1536 GNLMP1836 GNLMP1848 GNLMP2448 Screen Area 4.32 m2 5.4 m2 6.48 m2 8.64 m2 11.52 m2 Vibration Direction Angle 38~52 Degree Vibration Frequency 16 Hz Power 2*2.9kW 2*2.9kW 2*4.5kW 2*5kW 2*7kW Double Amplitude 4~6mm Screen Opening 0.2~25mm Dry Material Discharge Capacity 5~18 m3/h 6~20 m3/h 8~28 m3/h 10~40 m3/h 18~80 m3/h Installation Inclination ±4 Degree Remark - The above parameters are for reference only and can be adjusted according to the customer's situation. The final quotation and technical agreement shall prevail.

- The handling capacity of materials with the same size and different working conditions varies greatly. Please consult GN company for details.

The above specification and parameters for reference only. Features of Classification Vibrating Screen:

- Screen Surface: Made of wire mesh or perforated plates with different-sized openings for particle classification.

- Vibration Mechanism: Utilizes electric motors with eccentric weights or vibrating motors to control material movement.

- Multiple Decks: Stacked screens with varied openings separate particles into size fractions.

- Inlet and Outlet: Material is fed through an inlet and discharged from outlets at the bottom or sides.

- Sturdy Support Structure: Provides stability and include vibration-absorbing components.

- Screening Efficiency: Accurate particle separation based on screen settings and design.

- Adjustability: Allows customization of vibration intensity, angle, and screen size for optimal performance.

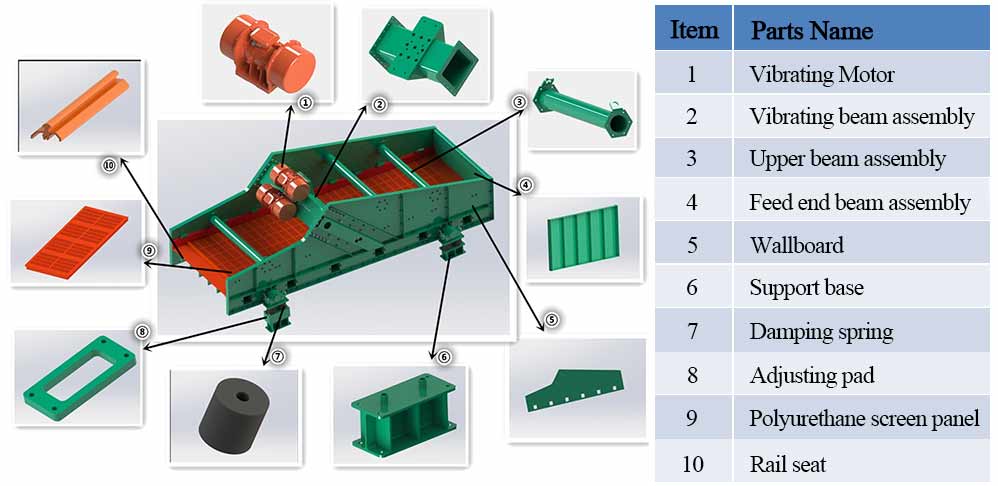

Features of Classification Vibrating Screen Main Components: