Welcome to GN Solids Australia

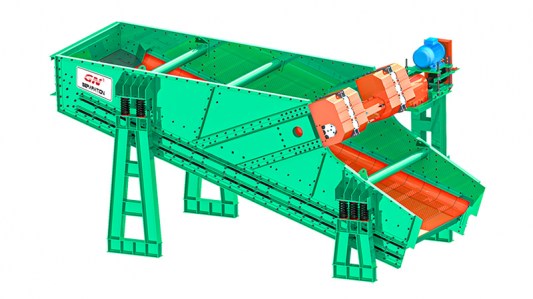

Flip-Flow Vibrating Screen

The large Flip-Flow Vibrating Screen (also known as the large-scale tension screen) is a screening device used for material separation in industries such as mining, metallurgy, and chemical.

-

The large Flip-Flow Vibrating Screen (also known as the large-scale tension screen) is a screening device used for material separation in industries such as mining, metallurgy, and chemical. Compared to other screening machines, this equipment adopts a special structure and vibration method, resulting in higher output, higher screening efficiency, smaller footprint, lower noise, longer lifespan, and better suitability for screening high-density materials.

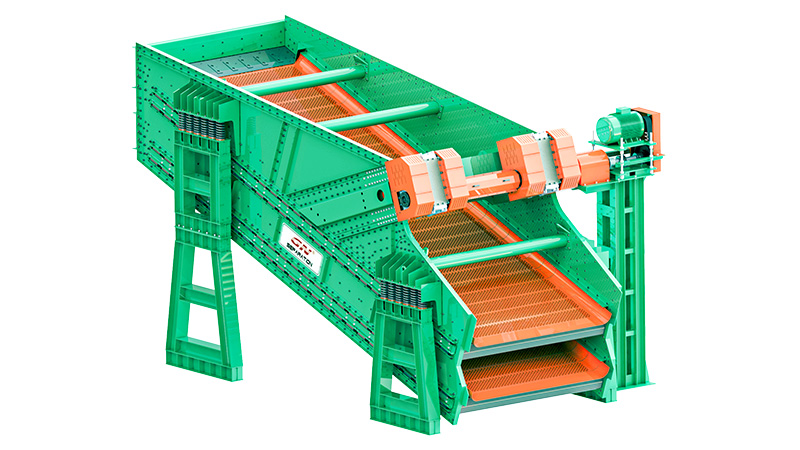

Large Flip-Flow Vibrating Screen- Single Deck

Model GNFS2461 GNFS3061 GNFS3085 GNFS3673 GNFS3690 GNFS43100 Screen Area m2 14.64 18.3 25.5 26.28 32.4 43 Vibration Direction Angle° 40 Vibration Frequency Hz 12.5~13.33 Power kW 30 30 45 45 55 55 Double Amplitude mm 12~16 Mesh Size mm 6~25 Capacity t/h 110~440 200~550 260~700 300~800 350~900 350~950 Installation Inclination° 15~20 Remark - The above parameters are for reference only and can be adjusted according to the customer's situation. The final quotation and technical agreement shall prevail.

- The handling capacity of materials with the same size and different working conditions varies greatly. Please consult GN company for details.

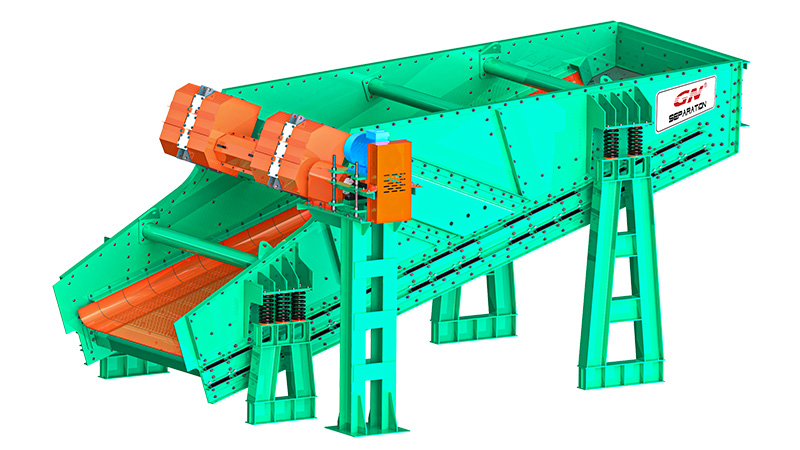

Large Flip-Flow Vibrating Screen- Double Deck

Model GNFD2461 GNFD3085 GNFD3690 GNFD43100 Screen Area m2 14.64×2 25.5×2 32.4×2 43×2 Vibration Direction Angle° 40 Vibration Frequency Hz 12.5~13.33 Power kW 30 55 55 90 Double Amplitude mm 12~16 Mesh Size mm 6~25 Capacity t/h 200~600 300~900 400~1000 600~1200 Installation Inclination° 15~20 Remark - The above parameters are for reference only and can be adjusted according to the customer's situation. The final quotation and technical agreement shall prevail.

- The handling capacity of materials with the same size and different working conditions varies greatly. Please consult GN company for details.

Large Flip-Flow Vibrating Screen Features:

- The large Flip-Flow Vibrating Screen consists of a vibrator, screen box, tensioning device connected to the suspension screen surface, screen surface, and frame. By generating vibration force, the vibrator layers and transmits the materials onto the screen surface. Multiple layers of screen meshes within the screen box accommodate the screening requirements of materials with different sizes and shapes. The vibrator's working principle involves the excitation force generated by the vibration motor through the exciter, which is transmitted to the screen mesh on the screen box frame. This causes the materials to exhibit a jumping motion on the screen plate, achieving layering and screening and completing the screening process. The tensioning device ensures the tightness and screening effect of the screen mesh, while the frame reinforces and supports the entire equipment.

- The Flip-Flow Vibrating Screen is an efficient screening equipment widely utilised in various industries, including pharmaceuticals, chemicals, and food. It effectively separates coarse and fine powders from raw material mixtures. The screen surface of the large-scale expandable screen is typically spacious, reaching tens of square metres, enabling the processing of substantial amounts of raw materials. Moreover, it offers high screening efficiency, facilitating the completion of a large volume of screening work in a short timeframe. Driven by a motor, this equipment operates stably, produces minimal noise, and is user-friendly in terms of operation and maintenance. Additionally, the large-scale expandable screen can be customised to meet specific production needs, ensuring adaptability to diverse production requirements.