3 Phase Decanter Centrifuge

-

GN 3-phase Decanter Centrifuge, also known as GN Tricanter, is a type of centrifuge used for the separation of three immiscible phases within a mixture. Operating on the principle of centrifugal force, this centrifuge efficiently divides complex mixtures into three distinct components, offering superior separation capabilities compared to its 2-phase counterpart.

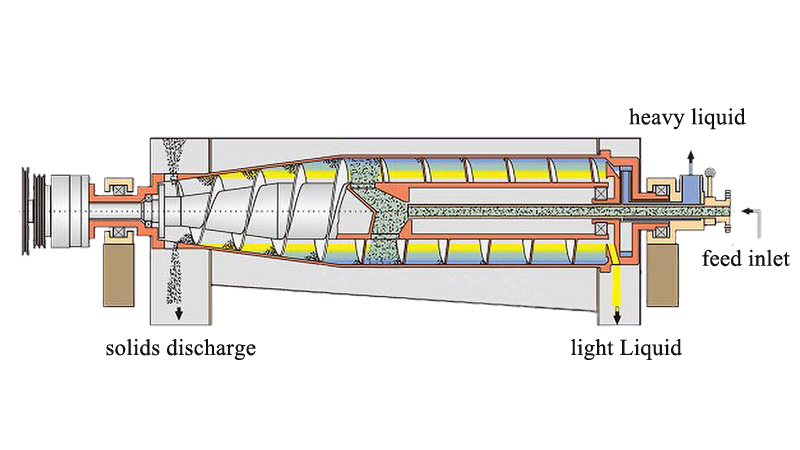

The process involves introducing the mixture into a rotating bowl, where the powerful centrifugal force rapidly segregates the different phases based on their densities. The heavier solid phase settles at the bottom, while the two liquid phases form separate outer layers, each with its unique density.

3 Phase Decanter Technical Parameters:

Model GNLWS-364 GNLWS-454 GNLWS-554 Type Continues Oil / Water / Solids Separation Bowl Dia 360mm 450mm 550mm Bowl Length 1567mm 1947mm 2347mm Capacity 5 m3/h 10 m3/h 15m3/h Max Speed 3986 RPM 3452 RPM 3123 RPM Max G Force 3200 G 3000 G 3000 G Diff. Speed 0-30 RPM 0-30 RPM 0-30 RPM Main Drive 22/30 KW 37/45 KW 55/75 KW Back Drive 7.5 KW 11/15 KW 18.5/22KW Lubrication Grease Grease Oil Pump Oil Pump Size N/A N/A 0.37 KW Feed Material Solids Less 10% and Particle Size less than 2mm The above specification and parameters for reference only. GN Decanter Centrifuge’s Bowl Assembly Features:

- Bowl Material: High-grade Duplex Stainless Steel SS2205 for durability and corrosion resistance.

- Solids Discharge Port: Reinforced with Tungsten Carbide insert for wear resistance.

- Bearing: Premium bearings from SKF or Japan NSK for efficient operation.

- Gearbox Type: Planetary wheel design for smooth power transmission.

- Screw Conveyor Material: Duplex Stainless Steel SS2205 for robustness.

- Material Distribution Nozzle: Strengthened with Tungsten Carbide insert for durability.

- Screw Conveyor Wear Protection: Equipped with Tungsten Carbide tiles for abrasion resistance.

- Adjustable Differential Speed: Allows optimization of separation performance based on specific conditions.

3-Phase Decanter Adjustable Separation:

The decanter offers adaptable separation for varying liquid phase proportions. An adjustable impeller efficiently discharges the "heavy" liquid phase, and a modification mechanism allows altering the separation line for desired results. Enhances versatility for diverse industrial applications.

3 Phase Decanter Features:

- The 3-phase decanter centrifuge presents a prominent advantage in its capacity to effectively separate three immiscible phases within complex mixtures.

- Its continuous operation capability ensures uninterrupted processing, while the high separation efficiency guarantees precise and clean division of the three components.

- This centrifuge finds versatile applications across diverse industries, including oil and gas, wastewater treatment, and chemical sectors, where it excels in tasks such as crude oil dewatering, sludge dewatering, and oil-water separation.

- Equipped with advanced automation and control systems, it allows for remote monitoring, parameter adjustments, and seamless integration with other equipment, enhancing operational efficiency.

- Its robust construction ensures durability in demanding environments, and its adjustable parameters enable operators to optimize the separation process for specific mixture characteristics and requirements.

- Overall, the 3-phase decanter centrifuge stands as an indispensable and proficient tool in modern industrial processes, catering to large-scale operations and offering utmost precision in complex mixture separation.