Drilling Mud Centrifuge

-

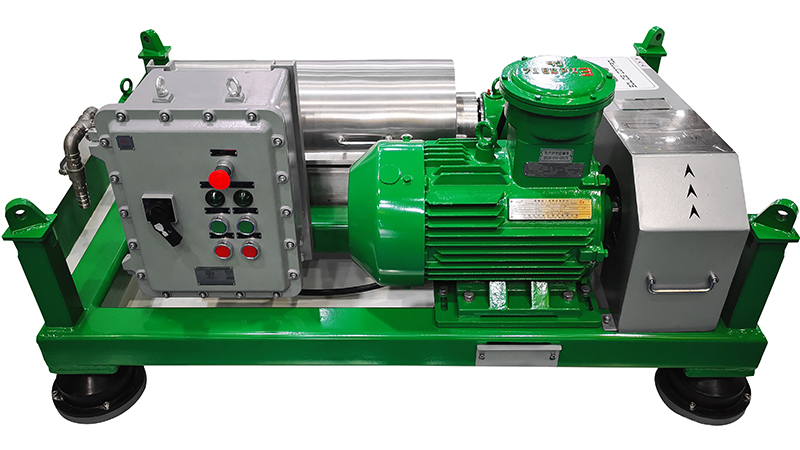

A drilling mud centrifuge is a critical piece of equipment used in the drilling industry to separate solids from liquid in drilling fluids. It is also known as a decanting centrifuge. The drilling mud centrifuge works on the principle of centrifugal force, which separates the heavier and larger solid particles from the liquid phase.

GN High Configuration Decanter Centrifuge Parameter

Model GNLW363D-GP GNLW363D-VFD GNLW453C-VFD GNLW553C-VFD Bowl Diameter 360mm(14inch) 360mm(14inch) 450mm(18inch) 550mm(22inch) Bowl Length 1271mm(50inch) 1271mm(50inch) 1540mm(61inch) 1800mm(71inch) Max. Capacity 200GPM(45m3/h) 200GPM(45m3/h) 352GPM(80m3/h) 484GPM(110M3/h) Effective Capacity 132GPM(30m3/h) 132GPM(30m3/h) 264GPM(60m3/h) 400GPM(90m3/h) Max Bowl Speed 3900RPM 3900RPM 3200RPM 3000PRM Typical Bowl

Speed3200RPM 0~3200RPM 0~2800RPM 0~2500RPM Max G-Force 3063 3063 2578 2719 Typical G-Force 2062 0~2062 0~1973 0~1888 Separation point 2~5µm 2~5μm 2~5µm 2~5μm Differential Speed 40 0~40 0~35 0~45 Gearbox Torch 3500N.M 3500N.M 7500N.M 12000N.M Gear Box Ration 57:1 57:1 57:1 35:1 Main Drive Motor 37KW(50HP) 37KW(50HP) 55KW(75HP) 90KW(120HP) Back Drive Motor 11KW(15HP) 11KW(15HP) 22KW(30HP) 37KW(50HP) Recommend Pump 7.5KW(10HP) 7.5KW(10HP) 15KW(20HP) 22KW(30HP) EX Standard ExdIIBt4 / IEC EX/ ATEX Electric Carbinet Exd Standard PLC+Positive Presurized Weight 3500KG 3400KG 4580KG 5840KG Dimension(mm) 3260x1467x1352 3260x1467x1352 3824x1798x1317 4293x1978x1381 The above specification and parameters for reference only.

GN Economic Configuration Decanter Centrifuge Parameter;

Model GNLW223D GNLW224EP-VFD GNLW452C-GP Bowl Diameter 220mm(9inch) 220mm(9inch) 450mm(18inch) Bowl Length 670mm(26.4inch) 924mm(36.4inch) 1105mm(43inch) Max. Capacity 40GPM(9m³/h) 40GPM(9m³/h) 250GPM(57M3/h) Effective Capacity 26GPM(6m³/h) 26GPM(6m³/h) 176GPM(40m3/h) Max Bowl Speed 4500RPM 4500RPM 1800RPM Typical Bowl

Speed3800RPM 0~3800RPM 1800RPM Max G-Force 2492 2492 815 Typical G-Force 1777 1777 815 Separation point 2~5micron 2~5micron 5~7Micron Differential Speed 10/20/30 10/20/30 32 Gearbox Torch 500N.M 500N.M 3500N.M Gear Box Ration 35:1 35:1 57:1 Main Drive Motor 11Kw(15HP) 11Kw(15HP) 37KW(50HP) Back Drive Motor N/A N/A N/A Recommend Pump 3Kw 3Kw 11KW(15HP) EX Standard ExdIIBt4 / IEC EX/ ATEX Electric Carbinet Exd Standard Exd Standard Exd Standard Weight 850KG 850KG 3410KG Dimension 1924x1050x725mm 1924x1050x725mm 2939x1748x1320mm The above specification and parameters for reference only.

The drilling mud centrifuge is used to remove the solids that are too small to be removed by the shale shaker. The centrifuge is capable of removing solids as small as 2 to 5 microns in size. This is important because smaller solids can cause significant damage to the drilling equipment, leading to costly repairs and downtime. The drilling mud centrifuge helps to reduce such damage and ensures uninterrupted drilling operations.

The drilling mud centrifuge consists of a rotating drum that is filled with the drilling fluid. As the drum rotates at high speeds, the centrifugal force causes the solids to settle on the wall of the drum while the liquid is forced through the screen and discharged into the clean tank. The solids are then scraped off the wall of the drum and discharged through a separate outlet.

One of the most significant advantages of the drilling mud centrifuge is its efficiency and cost-effectiveness in separating solids from drilling fluids. The centrifuge reduces the disposal cost of waste solids and helps to maintain the properties of the drilling fluid. This is important because the drilling fluid is critical to the success of the drilling operation.

The drilling mud centrifuge is also useful in recycling drilling fluids that can be reused in the process. The recycled drilling fluids are cost-effective and help to reduce the overall cost of drilling operations. Additionally, the drilling mud centrifuge reduces the environmental impact of the drilling activities by reducing the amount of waste produced.

In conclusion, the drilling mud centrifuge is an essential piece of equipment in the drilling industry. It is used to separate solids from drilling fluids, reduce the disposal cost of waste solids, maintain the properties of the drilling fluid, and recycle drilling fluids. The drilling mud centrifuge is an efficient and cost-effective way of ensuring the success of drilling operations while minimizing the environmental impact of the drilling activities.