Welcome to GN Solids Australia

Oil & Gas Drilling Mud System

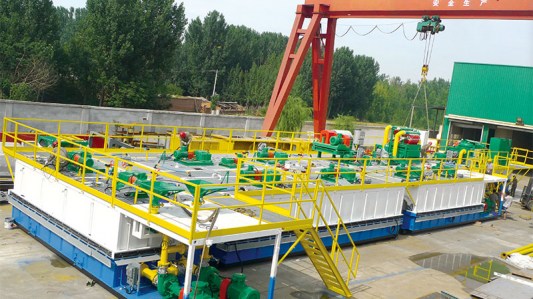

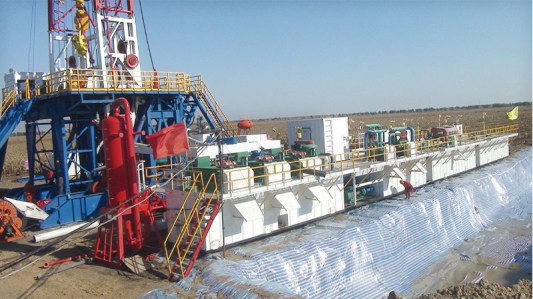

The Oil & Gas Drilling Mud System is a comprehensive solids control system utilized in oil and gas drilling operations.

-

The Oil & Gas Drilling Mud System is a comprehensive solids control system utilized in oil and gas drilling operations. It consists of multiple tanks and various equipment designed to effectively manage drilling mud circulation. GN Solids Control offers a range of mud systems tailored to different rig sizes, spanning from 250HP to 3000HP, with varying capacities.

GN Oil & Gas Drilling Mud System incorporates several essential solids control equipment, including:

- Shale Shaker: This primary solids control device is responsible for separating particles larger than 100 microns from the drilling mud.

- Desander: As the second phase of solids control, the desander targets cuttings sized around 40 microns, further enhancing the efficiency of particle removal.

- Desilter: Operating as the third phase of solids control, the desilter focuses on cuttings sized around 20 microns, ensuring finer solids are effectively removed from the drilling mud.

- Decanter Centrifuge: With a separation range of 2-7 microns, the decanter centrifuge plays a crucial role in separating ultra-fine solids from the drilling mud.

In addition to the solids control equipment, the GN Oil & Gas Drilling Mud System incorporates various mud tanks, each serving a specific function:

- Silting Mud Tank (Shaker Tank): This tank is dedicated to collecting the mud discharged from the shale shaker, allowing for further processing and solid removal.

- Active Mud Tank: This tank serves as the primary mud storage and mixing area, facilitating the active circulation of mud throughout the drilling process.

- Suction Mud Tank: The suction mud tank is responsible for receiving and temporarily storing mud from external sources, such as mud pumps or mud hoppers.

- Mixing Mud Tank: As the name suggests, this tank is utilized for blending and mixing various additives with the drilling mud to maintain desired properties and composition.

- Storage Mud Tank: This tank provides additional storage capacity for surplus drilling mud, ensuring an adequate supply is readily available when needed.

GN Solids Control, as a leading manufacturer of oil and gas drilling mud systems, holds certifications such as API, Europe CE, and Russia TP and TC. The explosion-proof standards of the products meet IEC Ex or ATEX certification requirements for Zone 1 and Zone II applications.