WHO WE ARE

Industry Separation Equipment For Global Market

Mining, Civil Construction, Oil & Gas Drilling, Wastewater & Sludge and others.

GN Solids Australia

GN Australia based in Brisbane, Queensland

Provide Industry Separation Equipment to Australia, New Zealand, Papua New Guinea and the wider Australia Pacific Region.

Learn More

GN Solids Control

GN China Headquarter is in Langfang, Hebei Province

Design and Manufacture Solids Control Equipment, Centrifuge Equipment, Vibrating Screen for Global Market.

Learn More

GN Solids America

GN America based in Houston, Texas

Provide Industry Separation Equipment sales and service to USA, Canada, and South America Countries.

Learn More

GN Case Studies in Australia

Since 2009, we have proudly served the Australian market from our headquarter.

Civil Construction

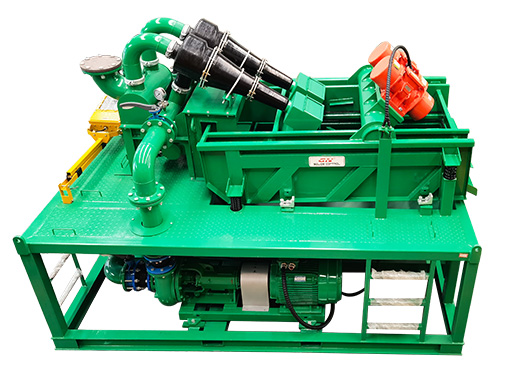

Trenchless Mud Recycling Unit

Oil& Gas Drilling

Solids Control Equipment

Mining Separation

Dewatering Decanter Centrifuge

Hydrovac Slurry

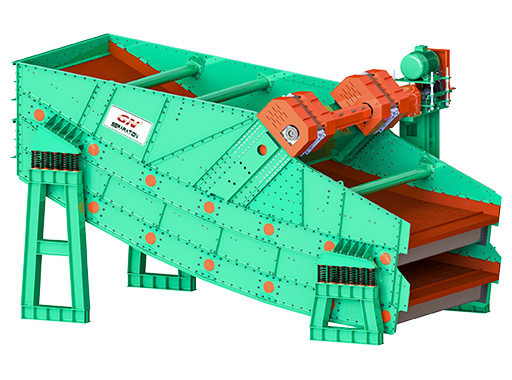

Dewatering Vibrating Screen

Our Advantage

GN Solids not only provide individual separation equipment, but also provide complete package of separation system or mud cleaning system to our customer.

Why Choose GN Solids?

Equipment works in 70+ Countries, Local support from Brisbane.

3 Factories total area 110,000㎡ with advanced production machines.

ISO9001, ISO14001, API Q1, Europe CE certified and ERP + Cloud Management System.

Coming Events

GN will attend 2024 Fieldays at Mystery Creek, Hamilton, NZ on 12 — 15 June, 2024.

Fieldays 2024

Mystery Creek, Hamilton, NZ

S27. GN Solids Australia will attend the International Mining and Resources Conference (IMARC) at ICC Sydney on 29-31 Oct 2024.

IMARC Mining 2024

Australia

GN Solids Australia attended the AOG Energy 2024. PERTH CONVENTION& EXHIBITION CENTRE. 13-15 March .

BOOTH NUMBER IS L34 .

AOG Energy 2024

Australia